Hotline:0755-22277778

Tel:0755-22277778

Mobile:13826586185(Mr.Duan)

Fax:0755-22277776

E-mail:duanlian@xianjinyuan.cn

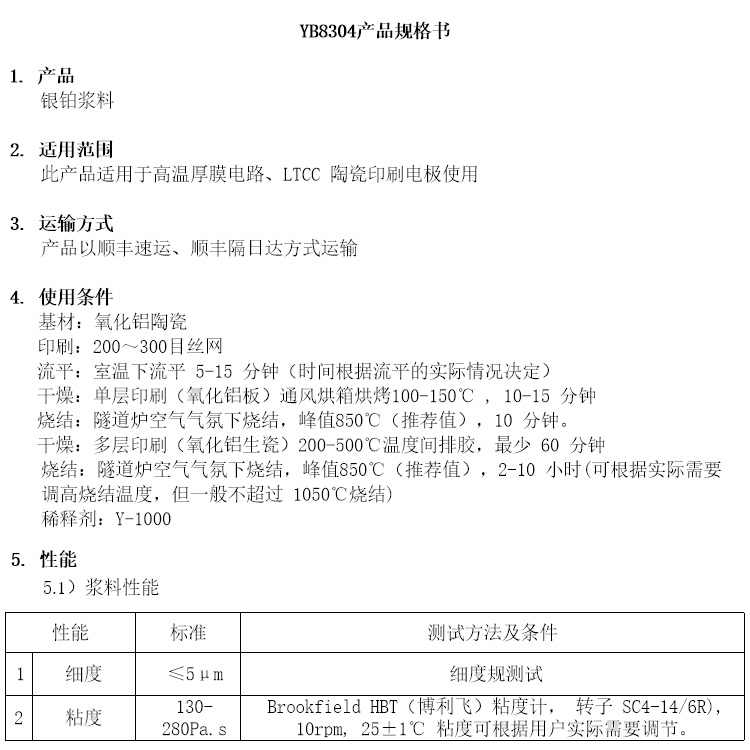

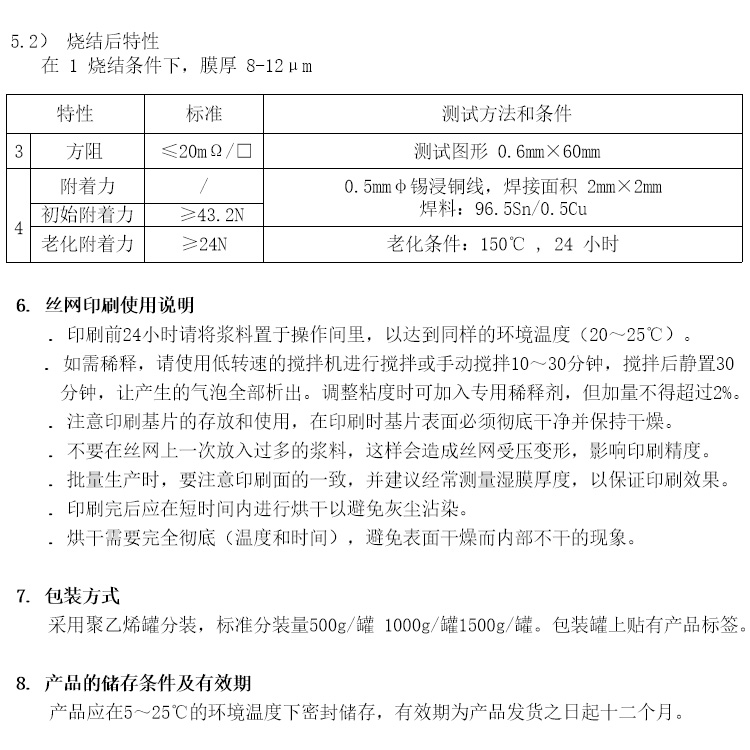

Advanced Institute of Technology silver platinum paste has a wide range of applications in the electronics and electrical industries, mainly used for general wiring, resistor end connections, and lead connections. Its excellent conductivity, solder resistance, and oxidation resistance make silver platinum paste an important material in these fields.

+86-13826586185

Silver platinum paste is mainly composed of silver platinum alloy powder, binders (such as binders), and organic carriers. Among them, silver and platinum are the main components of the conductive phase, while the binder and organic carrier play a role in bonding the conductive phase particles together and endowing the slurry with certain fluidity and adhesion.

Product Features

Conductivity: Silver platinum paste has excellent conductivity, with a square resistance value usually less than or equal to 4m Ω/port, which can meet the conductivity requirements of various electronic components.

Solder resistance: Silver platinum paste exhibits excellent performance in high-temperature welding environments, with good resistance to solder corrosion and the ability to maintain stable performance.

Oxidation resistance: The sintered silver platinum alloy conductive film has good oxidation resistance and can resist oxidation corrosion to a certain extent.

Solderability: Silver platinum paste has good weldability, making it easy to solder and connect with other electronic components.

Adhesion: Silver platinum paste has a high initial adhesion and can firmly adhere to the surface of the substrate.

Production process

Mixing and Grinding: After mixing silver platinum powder with binder and organic carrier in a certain proportion, thorough grinding is carried out to evenly disperse each component and form a stable slurry.

Sintering temperature: During the preparation process of silver platinum slurry, it is usually necessary to treat it at a sintering temperature of around 850 ℃ to form a dense silver platinum alloy conductive film.

Workshop Display

Advanced Institute (Shenzhen) Technology Co., Ltd, © two thousand and twenty-onewww.leird.cn. All rights reservedGuangdong ICP No. 2021051947-1 © two thousand and twenty-onewww.xianjinyuan.cn. All rights reservedGuangdong ICP No. 2021051947-2