Hotline:0755-22277778

Tel:0755-22277778

Mobile:13826586185(Mr.Duan)

Fax:0755-22277776

E-mail:duanlian@xianjinyuan.cn

Advanced Institute Technology thick film silver platinum electrode paste is a high-performance conductive material, using silver platinum alloy as the conductive phase, with excellent oxidation resistance, solderability, and solder corrosion resistance. It is mainly used in high-performance thick film integrated circuits, automotive electronics and other fields, which can effectively improve the conductivity and stability of products. This slurry is made through precise mixing and grinding processes, ensuring high quality and consistency.

+86-13826586185

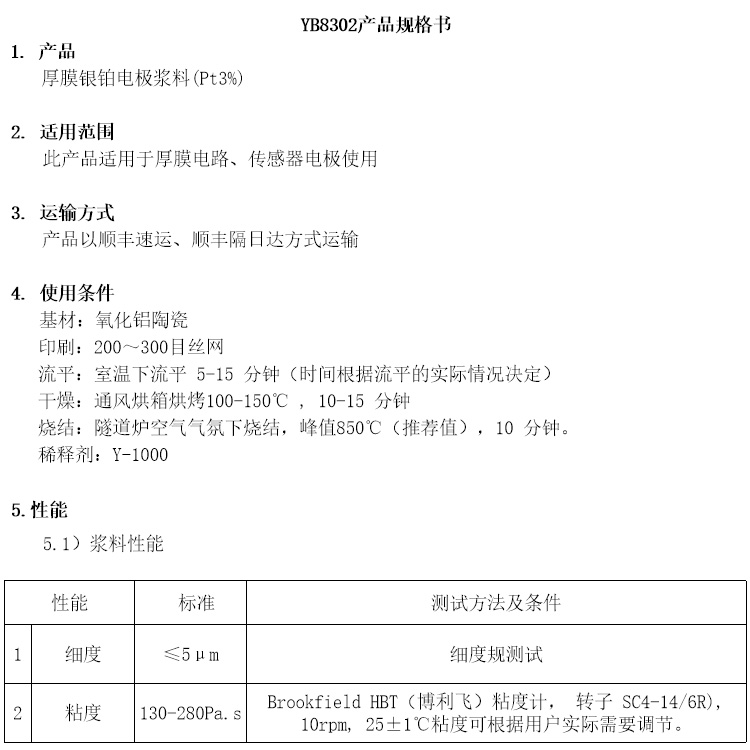

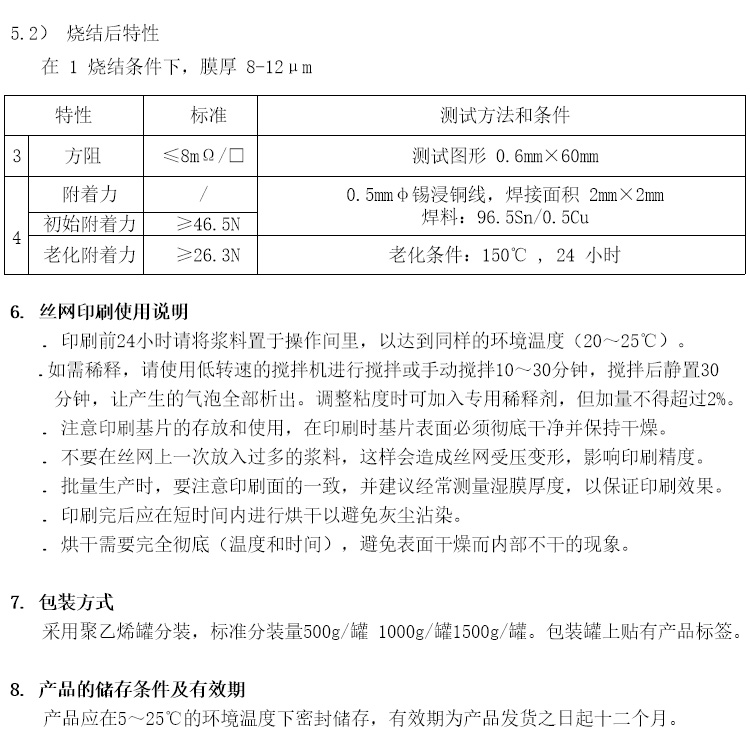

Thick film silver platinum electrode paste is a material used for manufacturing electronic components such as thick film circuits and sensor electrodes. This slurry combines the advantages of silver and platinum, with good conductivity and high chemical stability.

Product Features

Strong antioxidant capacity: Silver platinum alloy conductive film has good antioxidant performance in high temperature and harsh environments.

Good weldability: It has good weldability and resistance to solder corrosion, suitable for various welding processes.

High initial adhesion: The high initial adhesion on the substrate is beneficial for forming a stable electrode structure.

Superior conductivity: Silver platinum alloy has excellent conductivity, ensuring efficient electrical signal transmission of the electrode.

Production process

Preparation: Mix silver platinum alloy powder with binder, solvent, and other additives in specific proportions.

Printing: Using techniques such as screen printing to print the paste onto the substrate.

Drying: Drying is carried out using an infrared lamp or oven to remove solvents.

Sintering: Sintering is carried out at a specific temperature to tightly bond metal particles with the substrate.

Workshop Display

Advanced Institute (Shenzhen) Technology Co., Ltd, © two thousand and twenty-onewww.leird.cn. All rights reservedGuangdong ICP No. 2021051947-1 © two thousand and twenty-onewww.xianjinyuan.cn. All rights reservedGuangdong ICP No. 2021051947-2