Hotline:0755-22277778

Tel:0755-22277778

Mobile:13826586185(Mr.Duan)

Fax:0755-22277776

E-mail:duanlian@xianjinyuan.cn

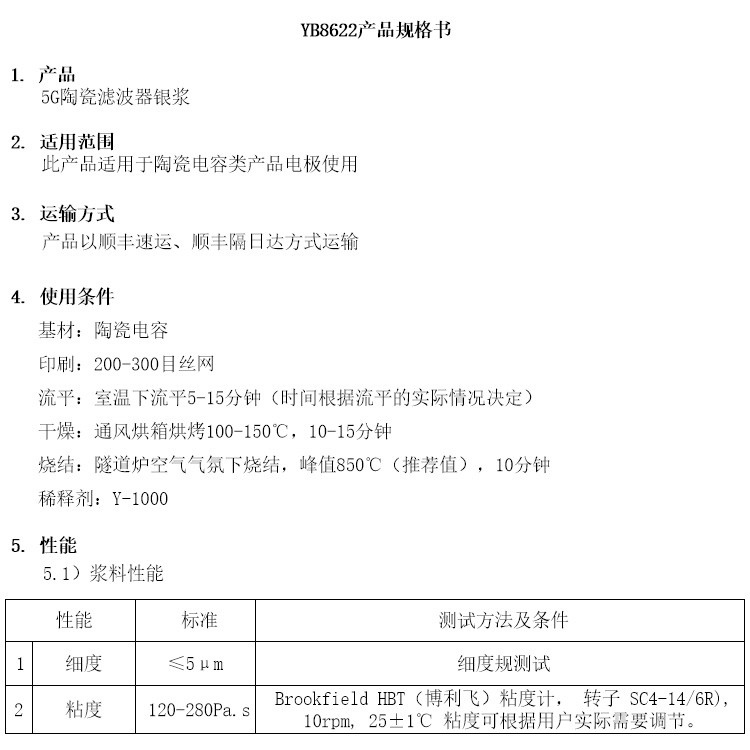

Advanced Institute Technology 5G Ceramic Filter Silver Paste is a filling type conductive paste with silver powder as the conductive filler, mainly used to form a conductive layer on the surface of ceramic dielectric filters. This conductive layer needs to have high conductivity, high density, good adhesion, and weldability to ensure the stability and efficiency of the filter during high-frequency signal transmission.

+86-13826586185

5G ceramic filter silver paste is a filling type conductive paste, mainly composed of silver powder, and containing resin, glass powder, solvent, and additives. In the production process of ceramic filters, conductive silver paste is coated on the ceramic substrate through specific processes such as screen printing, spraying, etc., and then subjected to subsequent treatments such as sintering to form a silver conductive layer with high conductivity, high density, good adhesion, and weldability.

Product Features

Conductivity: Silver has excellent conductivity, which enables silver paste to effectively reduce signal loss in filters.

Thermal expansion coefficient: The thermal expansion coefficient of silver paste is close to that of ceramic matrix, which can reduce the stress caused by temperature changes and improve the reliability of the filter.

Thermal stability: Silver paste can maintain stability at high temperatures and is suitable for the high-temperature sintering process of ceramic filters.

Welding performance: Metal components can be directly welded onto the silver layer, facilitating the integration of filters with other electronic components.

manufacturing process

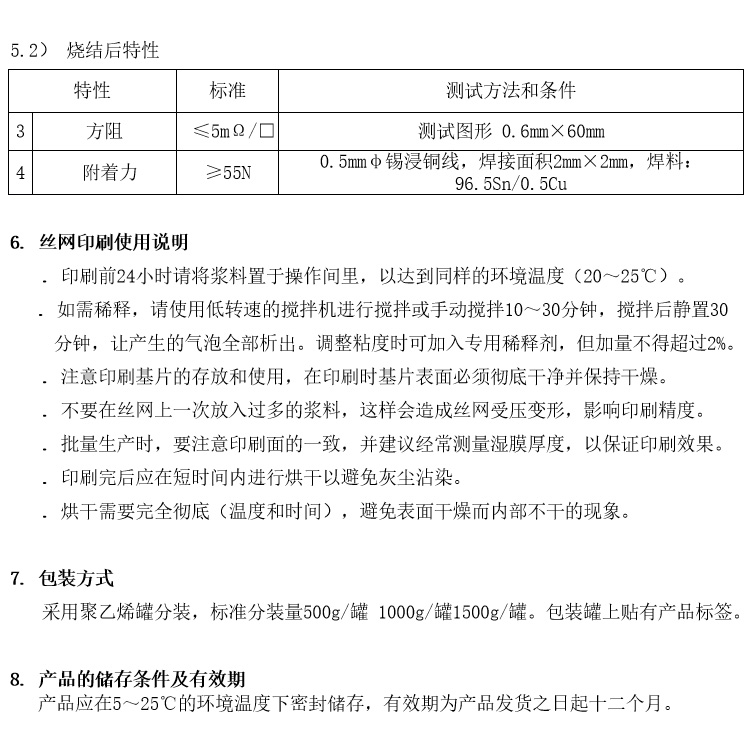

Printing: Silver paste is coated onto a ceramic substrate using methods such as screen printing to form the desired circuit pattern.

Curing: The silver paste is solidified by heating to form a stable metal layer. This can be achieved through high-temperature sintering or low-temperature solidification.

High temperature sintering: Suitable for certain types of silver paste, it fuses silver particles at high temperatures to form a continuous metal layer.

Low temperature curing: Some new silver pastes can be cured at lower temperatures, and advanced technology nano silver pastes can be cured between 120-200 ° C, which is very helpful for reducing energy consumption and improving production efficiency.

Workshop Display

Advanced Institute (Shenzhen) Technology Co., Ltd, © two thousand and twenty-onewww.leird.cn. All rights reservedGuangdong ICP No. 2021051947-1 © two thousand and twenty-onewww.xianjinyuan.cn. All rights reservedGuangdong ICP No. 2021051947-2