Hotline:0755-22277778

Tel:0755-22277778

Mobile:13826586185(Mr.Duan)

Fax:0755-22277776

E-mail:duanlian@xianjinyuan.cn

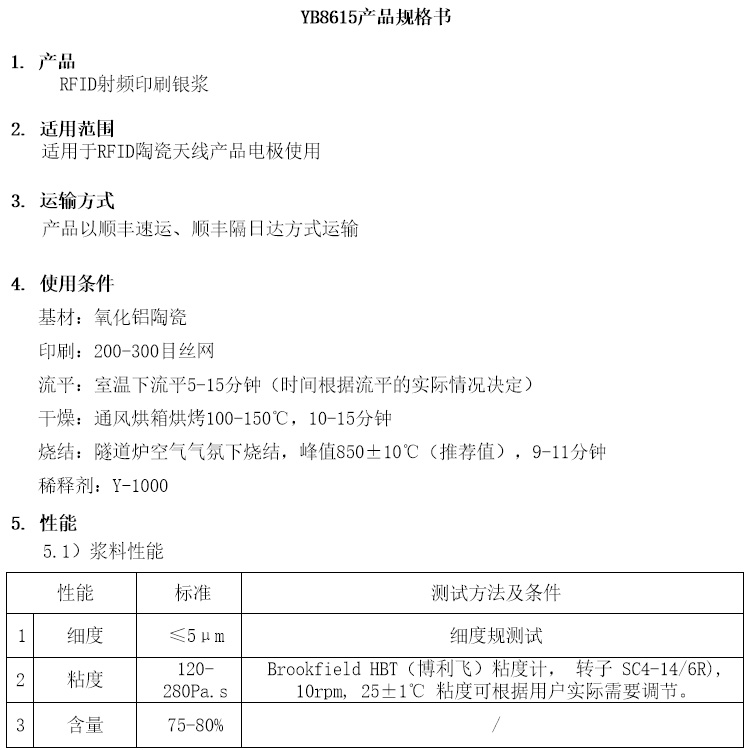

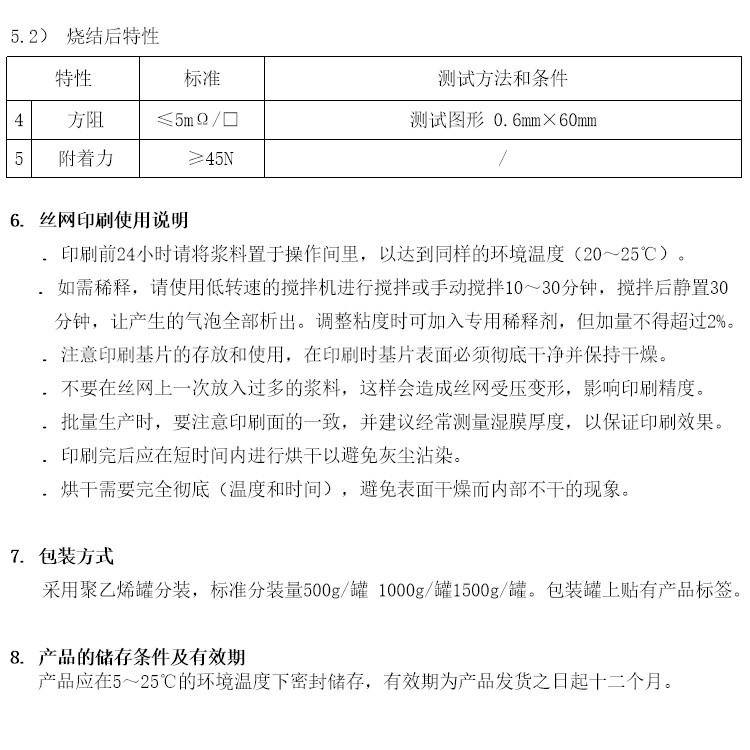

Advanced Institute Technology RFID Radio Frequency Printing Silver Paste: Tailored for RFID radio frequency identification technology, this printing silver paste has high adhesion, excellent conductivity, and stable radio frequency performance. This silver paste can easily achieve fine production of RFID tags through advanced printing technology, ensuring that the tags can work stably in various environments. Suitable for a wide range of fields such as logistics tracking, access control management, asset management, etc., to support the development of IoT technology.

+86-13826586185

RFID radio frequency printing silver paste is a high-performance conductive silver paste designed specifically for RFID electronic tag antennas. This silver paste has the characteristics of high conductivity and halogen-free, high dimensional accuracy, resistance to bending and hot pressing, and is very suitable for roll to roll production processes. Its excellent conductivity, good printability, and strong adhesion make it an ideal choice for RFID antenna printing.

Product Features

Conductivity: RFID printed silver paste has excellent conductivity and extremely low volume resistivity, which ensures stable transmission of RFID tags under high-frequency signals.

Adhesion: Silver paste has good adhesion to various materials such as glass, PET, etc., ensuring that printed circuits can maintain stable connections in complex environments.

Printing adaptability: Silver paste has good printing adaptability, with smooth printing line edges, flat surfaces, no burrs, fine line width, and thin thickness, suitable for high-precision printing needs.

Curing characteristics: There are multiple curing methods to choose from, such as room temperature curing, heating curing, UV curing, etc. Among them, low-temperature rapid curing silver paste can be cured in a relatively short time, improving production efficiency.

Production process

Mechanical ball milling method: crushing and refining silver powder through external mechanical force, suitable for the production of flake silver powder.

Chemical reduction method: Directly reducing silver salts to prepare flake silver powder can effectively control the rate of crystal nucleus formation and the preferential growth of crystal faces.

Liquid phase reduction method: Based on the principle of oxidation-reduction reaction, silver salts are reduced in a liquid phase system, suitable for industrial production

Evaporative condensation method: spherical silver powder is prepared by heating and vaporizing silver blocks, followed by condensation. The production cycle is short and the sphericity is good.

Silver salt decomposition method: Using a silver salt solution that can be thermally decomposed, spherical silver powder is obtained by heating decomposition and sintering.

Workshop Display

Advanced Institute (Shenzhen) Technology Co., Ltd, © two thousand and twenty-onewww.leird.cn. All rights reservedGuangdong ICP No. 2021051947-1 © two thousand and twenty-onewww.xianjinyuan.cn. All rights reservedGuangdong ICP No. 2021051947-2