Hotline:0755-22277778

Tel:0755-22277778

Mobile:13826586185(Mr.Duan)

Fax:0755-22277776

E-mail:duanlian@xianjinyuan.cn

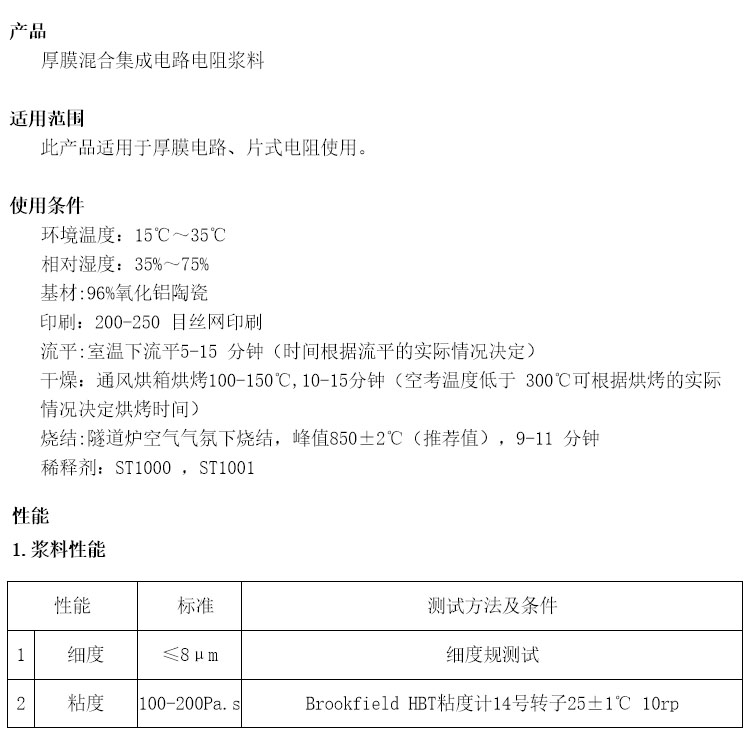

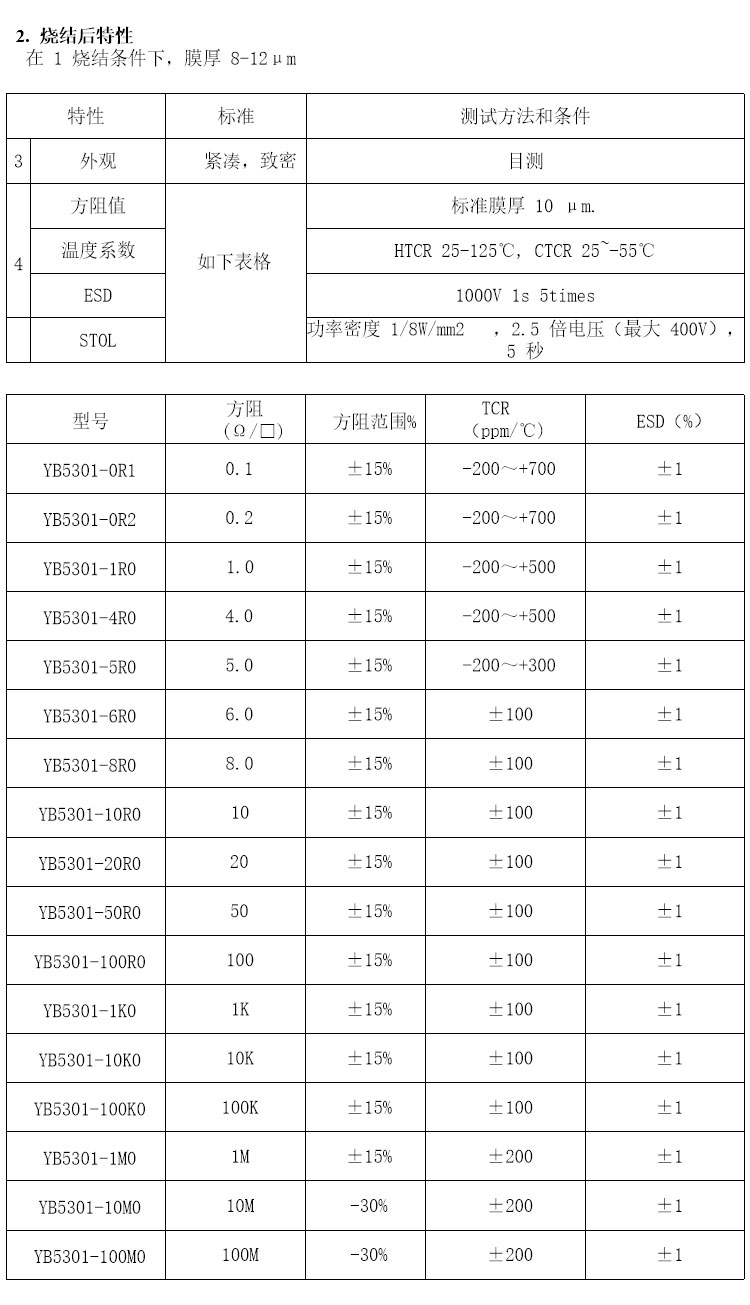

Thick film hybrid integrated circuit resistor paste adopts high-precision formula, designed specifically for thick film hybrid integrated circuits. This slurry has excellent stability and reliability, ensuring stable operation of circuits in high-power, high-frequency, and complex environments. Its main components include precious metal powder and special glass powder, which are sintered at high temperature to form a dense and uniform resistance layer, meeting the requirements of high-precision and low-noise circuits. Advanced Institute of TechnologyPrecious metal paste, can be customized according to needs; Welcome to consult.

+86-13826586185

Thick film hybrid integrated circuit resistor paste, as an important component of electronic paste, has broad application prospects in the field of electronic component manufacturing. With the continuous development of electronic technology, the performance requirements for thick film resistor paste are also increasing. Therefore, continuously developing new technologies, optimizing production processes, and improving product quality will be important directions for future development.

Product Features

Resistance value: The resistance value range of the resistance paste is wide and can be adjusted as needed.

Stability: It has good chemical stability, thermal stability, and moisture resistance, ensuring that the resistance value remains stable for a long time.

Accuracy: The resistance value has high precision, which can meet the manufacturing needs of high-precision electronic components.

Adhesion and aging adhesion: Excellent adhesion and aging adhesion ensure that the resistive film layer is not easily peeled off or failed during long-term use.

Production process

Slurry preparation: Mix the functional phase, glass phase, organic carrier, and modifier evenly according to the formula to make a slurry.

Screen printing: Using a printing machine to screen print the paste onto a substrate through the production of circuit patterns.

High temperature sintering: The printed substrate is sintered in a high-temperature sintering furnace to form a good fusion and network interconnection between the slurry and the substrate, and to stabilize the resistance of the thick film resistor.

Laser resistance adjustment: Use a laser resistance adjustment machine to adjust the resistance value of the thick film resistor printed on the sintered circuit substrate to the specified requirements.

Workshop Display

Advanced Institute (Shenzhen) Technology Co., Ltd, © two thousand and twenty-onewww.leird.cn. All rights reservedGuangdong ICP No. 2021051947-1 © two thousand and twenty-onewww.xianjinyuan.cn. All rights reservedGuangdong ICP No. 2021051947-2