Hotline:0755-22277778

Tel:0755-22277778

Mobile:13826586185(Mr.Duan)

Fax:0755-22277776

E-mail:duanlian@xianjinyuan.cn

Advanced Institute Technology's printing platinum paste has excellent conductivity and chemical stability, making it suitable for high-precision printing processes. Platinum powder particles are small and evenly dispersed, and the electrode pattern is clear after printing. Wide sintering temperature range and strong bonding with various substrates. The product is environmentally friendly and halogen-free, compliant with RoHS standards, and widely used in the manufacturing of electronic components and circuit boards, improving equipment performance and reliability.

+86-13826586185

Printed platinum paste is a material specifically used for manufacturing various electronic components, especially those components that require operation at high temperatures, such as oxygen sensors, fuel cells, high-temperature sensors, etc. This slurry is mainly composed of platinum powder, binder, solvent, and possible additives, and is designed for coating by methods such as screen printing, inkjet printing, or spin coating.

Product Features

Conductivity: Good conductivity, suitable for applications that require high conductivity.

Chemical stability: Platinum is very stable to most chemicals and is suitable for use in harsh environments.

Corrosion resistance: Platinum is not easily corroded and can maintain its properties even under high temperature and pressure conditions.

Printability: Easy to apply by screen printing and other methods, facilitating mass production.

Adhesive strength: Good adhesive strength ensures good adhesion between the platinum electrode and the substrate.

Particle size distribution: A small and uniform particle size helps to form a smooth and dense coating.

Production process

Drying temperature:Pre drying can be performed using an infrared lamp or a 70 ℃ oven.

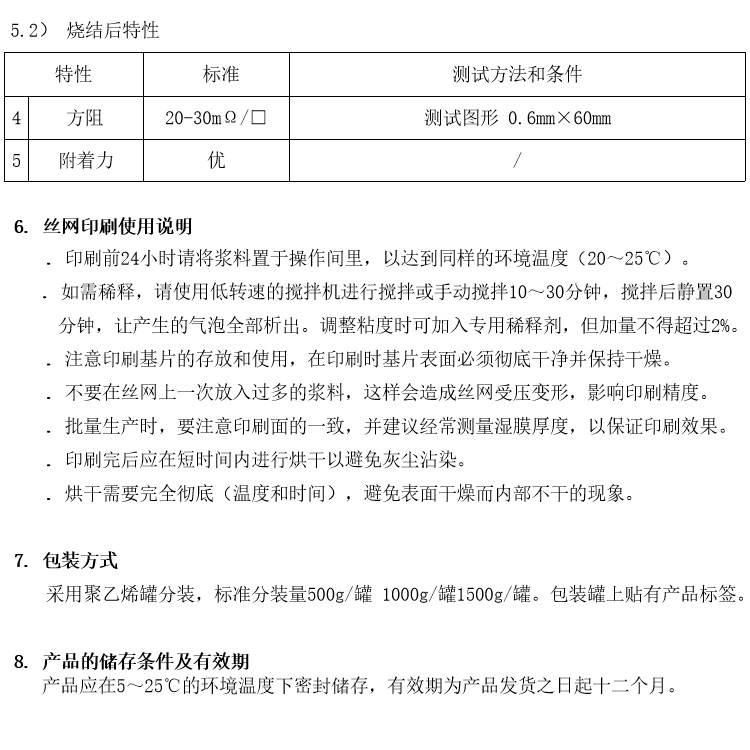

Sintering temperature:The sintering temperature range is 1450~1550 ° C, and the insulation time is 120 minutes at the peak temperature

Printing process:Use 300 mesh nylon or stainless steel wire mesh for printing.After printing, lay flat for 3 minutes to make the surface level.

Workshop Display

Advanced Institute (Shenzhen) Technology Co., Ltd, © two thousand and twenty-onewww.leird.cn. All rights reservedGuangdong ICP No. 2021051947-1 © two thousand and twenty-onewww.xianjinyuan.cn. All rights reservedGuangdong ICP No. 2021051947-2