Hotline:0755-22277778

Tel:0755-22277778

Mobile:13826586185(Mr.Duan)

Fax:0755-22277776

E-mail:duanlian@xianjinyuan.cn

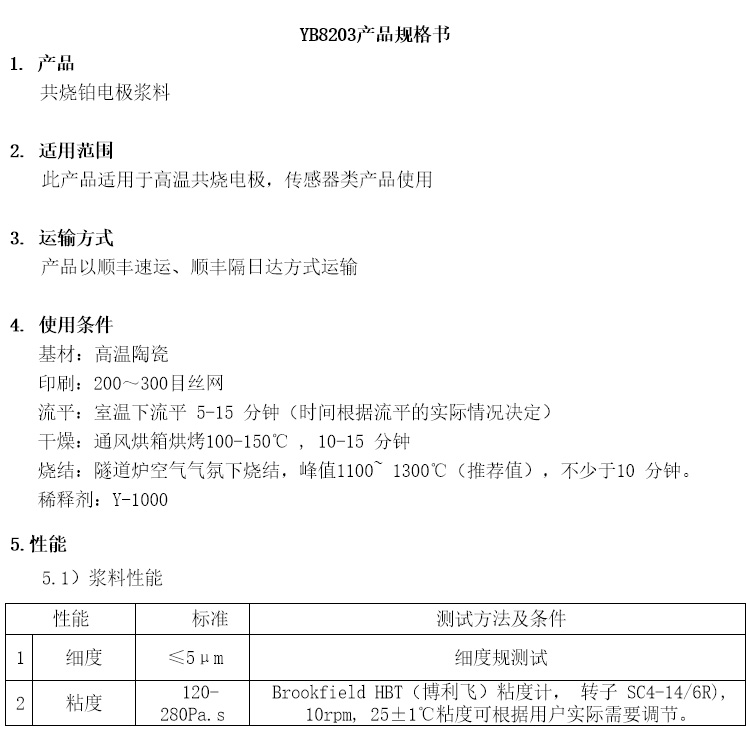

Advanced Institute Technology Co fired Platinum Electrode Slurry is a high-performance material used for making electrochemical sensors and biosensors. It has good conductivity, stability, and biocompatibility, and can be co fired with ceramic substrates at high temperatures to form a sturdy platinum electrode. This slurry is suitable for various applications such as preparing microelectrode arrays, gas sensors, and biofuel cells.

+86-13826586185

Co fired platinum electrode paste is a material specifically used for manufacturing conductive layers in electronic components such as oxygen sensors, thick film circuits, etc. The characteristic of this slurry is that it can be sintered together with the ceramic substrate at high temperatures without losing its conductivity.

Product Features

Composition and ratio: The co fired platinum electrode slurry is mainly composed of platinum (Pt) and other metals (such as silver Ag), and the mixing ratio can be designed according to different application requirements, such as 99.7% Ag/0.3% Pt to 99% Ag/1% Pt, etc.

Platinum, as a rare metal, has high conductivity and excellent corrosion resistance, which enables the slurry to maintain stable performance in various environments.

High temperature stability: able to work for a long time in high temperature environments (such as 1300 ° C) without losing its electrical performance, suitable for the production of electronic ceramic products that require high temperature resistance.

Fine printing applicability: This slurry is suitable for fine printing processes and can produce delicate and complex electronic ceramic products, such as flat oxygen sensor electrodes.

Highly customized: Flexible design can be made according to different application needs, providing highly customized products.

Production process

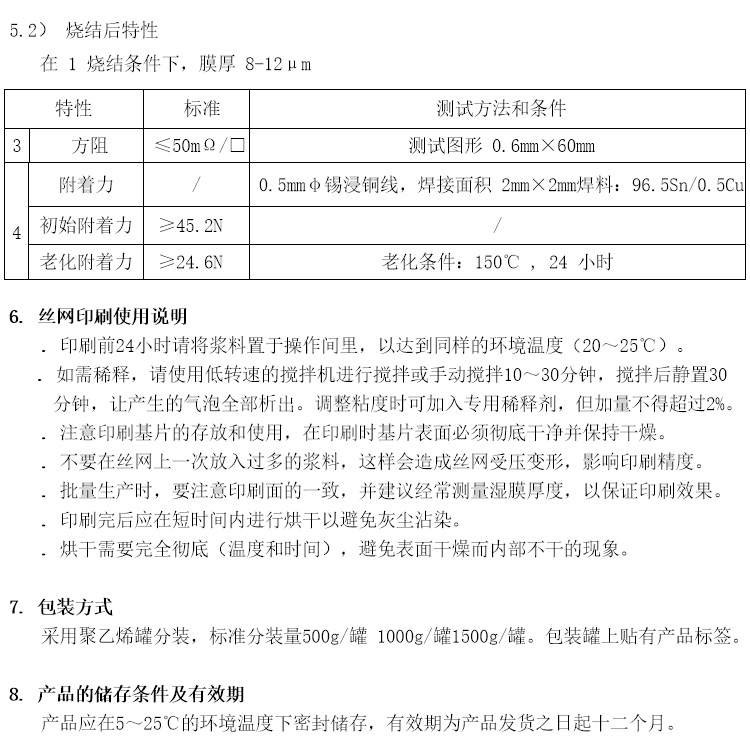

1. Raw material preparation and mixing: This stage mainly involves the preparation and precise weighing of raw materials such as platinum powder, organic carriers, additives, etc. These raw materials are mixed according to specific formula ratios to ensure the performance of the final product. During the mixing process, it is necessary to ensure that all raw materials are evenly dispersed without agglomeration.

2. Slurry preparation: After the raw materials are mixed evenly, prepare the slurry. This usually involves wet grinding, defoaming, and other treatments of the mixture to obtain a uniform and fine slurry. The wet grinding process helps to further refine the particles and improve the uniformity of the slurry; Defoaming can eliminate bubbles in the slurry and prevent defects from occurring in subsequent processes.

3. Printing process: The prepared co fired platinum electrode paste is coated onto the substrate through screen printing. During the printing process, it is necessary to control parameters such as the mesh size, printing pressure, and speed of the screen to ensure that the slurry is evenly and accurately coated on the substrate.

4. Sintering process: The printed slurry layer is sintered in a specific high-temperature environment to form tight connections between platinum particles and form a conductive platinum electrode layer. During the sintering process, it is necessary to precisely control parameters such as sintering temperature, holding time, and atmosphere to ensure the performance and quality of the platinum electrode layer.

Workshop Display

Advanced Institute (Shenzhen) Technology Co., Ltd, © two thousand and twenty-onewww.leird.cn. All rights reservedGuangdong ICP No. 2021051947-1 © two thousand and twenty-onewww.xianjinyuan.cn. All rights reservedGuangdong ICP No. 2021051947-2