Hotline:0755-22277778

Tel:0755-22277778

Mobile:13826586185(Mr.Duan)

Fax:0755-22277776

E-mail:duanlian@xianjinyuan.cn

Platinum electrode slurry, as a high-performance material, has shown wide application prospects in various fields such as flat oxygen sensors, electrolytic cells, electrochemical synthesis, and biosensors due to its unique conductivity, stability, and weldability. Adopting advanced manufacturing techniques to ensure optimal key indicators such as fineness, viscosity, and square resistance, meeting the high requirements of high-tech products for electrode materials. At the same time, the platinum electrode slurry also has a non porous characteristic, further improving the conductivity and service life of the electrode.

+86-13826586185

Platinum electrode paste is a key material used for manufacturing various electronic components such as sensors, fuel cells, solar cells, etc. It is usually composed of platinum particles, binder, and solvent, and can be printed or coated on a substrate to form a conductive platinum layer.

Product Features

High conductivity: Platinum, as a rare metal, has excellent conductivity, making platinum electrode paste widely used in the field of electronics.

Corrosion resistance: Platinum has strong chemical stability and can resist corrosion from various chemicals, extending the service life of electrodes.

High catalytic performance: Platinum electrode slurry performs well in the field of catalysts and can promote various chemical reactions.

Production process

Raw material preparation: Mix high-purity platinum powder with an appropriate amount of additives (such as glass binders, organic solvents, etc.) in a certain proportion.

Mixing and stirring: By using precision mixing equipment, the raw materials are thoroughly mixed evenly to form a uniform and delicate slurry.

Coating: The prepared platinum electrode slurry is coated onto a ceramic substrate or other base material through processes such as screen printing.

Drying: Drying treatment is carried out in an infrared lamp or oven to evaporate the organic solvents in the slurry.

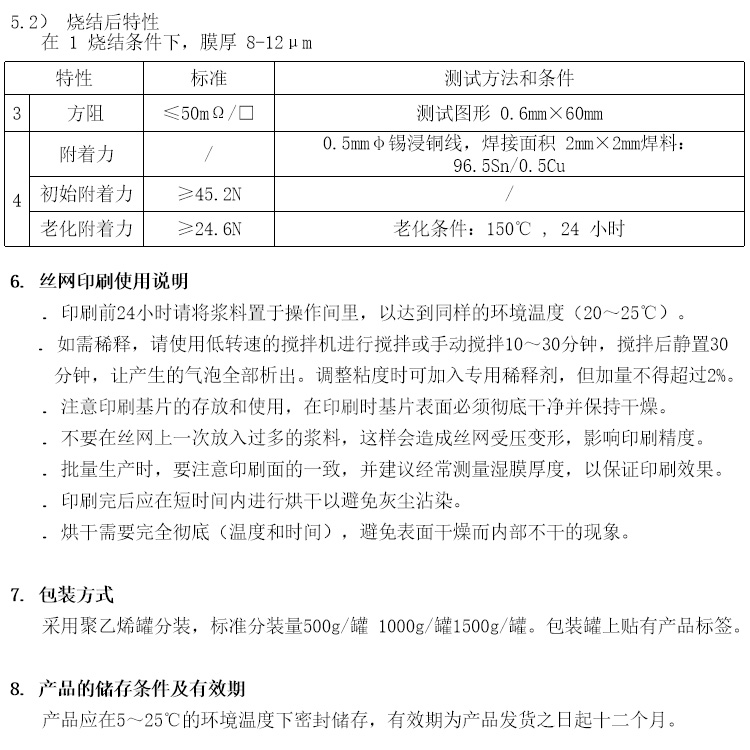

Sintering: Sintering treatment is carried out at high temperature to tightly bond platinum powder with the substrate and form a strong electrode layer.

Workshop Display

Advanced Institute (Shenzhen) Technology Co., Ltd, © two thousand and twenty-onewww.leird.cn. All rights reservedGuangdong ICP No. 2021051947-1 © two thousand and twenty-onewww.xianjinyuan.cn. All rights reservedGuangdong ICP No. 2021051947-2