Hotline:0755-22277778

Tel:0755-22277778

Mobile:13826586185(Mr.Duan)

Fax:0755-22277776

E-mail:duanlian@xianjinyuan.cn

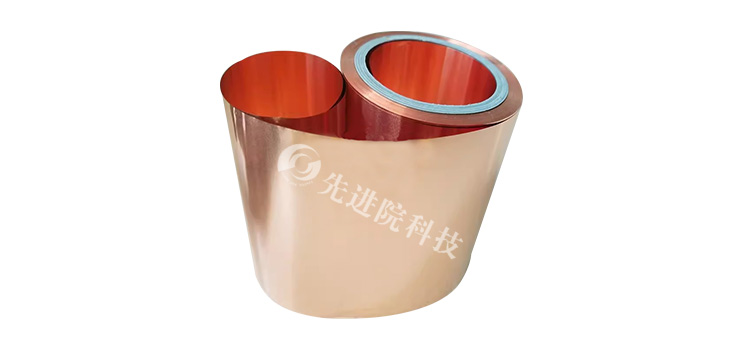

PET copper plated filmAs a material that combines the excellent properties of PET film with the conductivity and thermal conductivity of copper layer, it has been widely used in various fields such as electronic products, automotive parts, and household items. However, to fully leverage its advantages and avoid potential problems, it is necessary to clarify its optimal usage conditions and limitations. Determining these conditions helps optimize product design, improve production efficiency, reduce costs, and ensure the reliability and stability of the product in different environments.

The conductivity of PET copper plated film is one of its important characteristics. The copper layer endows the film with good conductivity and can be used to make electrodes, circuits, etc. However, its conductivity is affected by the thickness, purity, and copper plating process of the copper layer. For example, thicker copper layers typically have lower resistance, but also increase cost and weight. In addition, electromagnetic shielding performance is also a key aspect of electrical performance, which is related to the integrity and structure of the copper layer. Understanding the variation patterns of these performance parameters is the foundation for determining usage conditions.

The physical properties of PET copper plated film include flexibility, tensile strength, thermal expansion coefficient, etc. PET itself has good flexibility, which enables copper plated films to adapt to some bending and folding application scenarios. However, after copper plating, its flexibility may be affected to some extent, and it is necessary to evaluate the performance changes under different degrees of bending and frequencies. The tensile strength determines the stability of the material under stress, while the coefficient of thermal expansion affects its dimensional stability in temperature changing environments. These physical properties may have a significant impact on the performance of the product in different usage environments.

Chemical stability isPET copper plated filmImportant considerations. It needs to resist the erosion of various chemical substances, such as acidic and alkaline solutions, organic solvents, etc. Different chemical environments may cause corrosion of copper layers and degradation of PET films, thereby affecting their performance. Understanding the tolerance of PET copper plated film in different chemical substances is crucial for determining its usage conditions in the chemical industry, food packaging, and other fields.

Measure the resistance of PET copper plated film under different temperature and humidity conditions using the four probe method to determine the variation of its conductivity with environmental factors. Conduct electromagnetic shielding effectiveness testing, simulate electromagnetic interference environments at different frequencies, and evaluate their shielding effectiveness. Through these tests, it can be determined under what electrical environment PET copper plated film can maintain good conductivity and shielding performance, thereby determining its optimal usage conditions in electronic devices.

The tensile strength and elongation at break of PET copper plated film were tested using a tensile testing machine, and the changes in mechanical properties under different temperatures, humidity, and loading rates were studied. Conduct bending and folding tests, record the performance changes of the material during repeated bending and folding processes, and determine its maximum number of bending cycles and bending radius that it can withstand. By conducting thermal expansion coefficient tests, we can understand the dimensional changes of materials during temperature fluctuations, providing a basis for determining usage conditions in applications that require high dimensional accuracy.

Soak PET copper plated film samples in different concentrations of acid-base solutions and organic solvents, observe their surface changes after a certain period of time, measure their performance changes, such as weight loss, resistance changes, etc., to evaluate their chemical resistance. Conduct salt spray tests to simulate harsh marine environments and test the corrosion resistance of copper layers. Determine its usage limitations in different chemical environments through these chemical performance tests.

In electronic products,PET copper plated filmCommonly used for making flexible circuit boards, antennas, etc. Observe its performance under different working temperature, humidity, vibration and other conditions through actual production and usage testing. For example, in mobile antenna applications, evaluate the signal transmission efficiency at different frequency bands, as well as the performance stability after environmental tests such as high and low temperature cycling and vibration impact. Based on these practical application feedback, determine the optimal usage conditions and limitations in electronic products.

In the automotive industry, PET copper plated film can be used for components such as automotive antennas and sensors. Considering the complexity of the automotive usage environment, it is necessary to conduct actual road tests under different climatic conditions (high temperature, low temperature, high humidity, etc.) and mechanical vibration conditions. Observe the performance changes during long-term use, such as the adhesion of the copper layer and the stability of electromagnetic shielding performance, in order to determine its applicability and limitations in automotive components.

In household products, PET copper plated film may be used for lighting fixtures, home appliance casings, etc. to enhance the appearance, texture, and functionality of the products. Evaluate its wear resistance, pollution resistance, and stability under different lighting and temperature conditions in daily environments through practical testing. For example, in the application of lighting fixtures, observing their thermal stability and color changes after prolonged illumination can determine their optimal usage conditions in household products.

Based on the results of comprehensive experimental testing and practical application evaluation, analyze the environmental factors and working conditions that lead to the best performance of PET copper plated film under different performance indicators. For example, in terms of electrical performance, it is determined that it has the lowest resistance and the best electromagnetic shielding effect within a specific temperature and humidity range; In terms of physical performance, clarify under what bending and stretching conditions it can maintain structural integrity and stability; In terms of chemical properties, identify the types and concentration ranges of chemicals that it can tolerate. Combine these conditions to determine the optimal usage conditions for PET copper plated film.

Based on the results of experiments and practical applications, the analysis leads toPET copper plated filmDetermine the limiting conditions for performance degradation or failure factors. For example, when the temperature exceeds a certain threshold, its conductivity sharply decreases; Under the action of specific chemical substances, the copper layer undergoes severe corrosion. These conditions that lead to performance degradation are the limiting conditions of PET copper plated film. Clarifying these limitations can help avoid exceeding their tolerance range in product design and use, ensuring the reliability and safety of the product.

Determining the optimal usage and limiting conditions for PET copper plated film is a complex and systematic process that requires comprehensive consideration of its electrical, physical, and chemical properties, as well as obtaining accurate data through extensive experimental testing and practical application evaluation. Through in-depth research and analysis, scientific guidance can be provided for the application of PET copper plated films in different fields, enabling them to maximize their performance advantages under appropriate conditions while avoiding performance degradation or product failure caused by improper use. With the continuous development of material technology and the increasing diversification of application demands, research on the usage conditions of PET copper plated films will continue to deepen to meet the requirements of higher performance and more complex application scenarios.

The above data is for reference only, and specific performance may vary due to production processes and product specifications.

Advanced Institute (Shenzhen) Technology Co., Ltd, © two thousand and twenty-onewww.leird.cn. All rights reservedGuangdong ICP No. 2021051947-1 © two thousand and twenty-onewww.xianjinyuan.cn. All rights reservedGuangdong ICP No. 2021051947-2