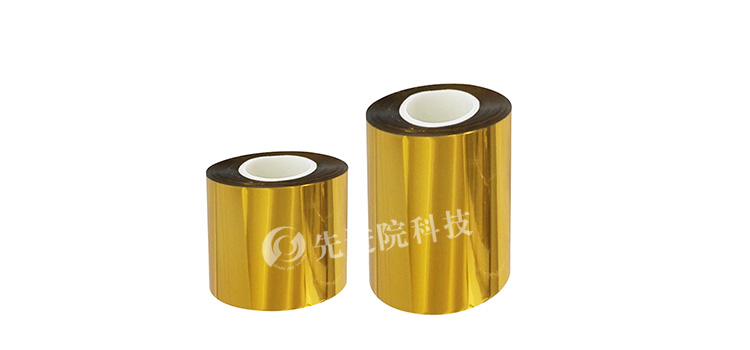

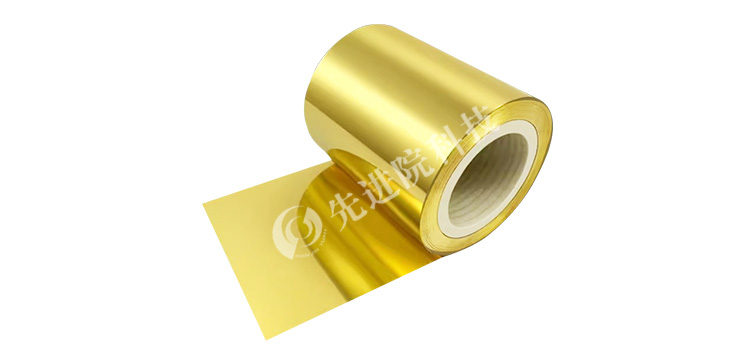

Polyethylene terephthalate (PET) gold plating film is widely used in the fields of electronics, optics, and packaging due to its excellent conductivity, corrosion resistance, and optical properties. However, ensuring the uniformity and consistency of PET gold plating film during the manufacturing process is key to improving product quality and production efficiency. This article will explore how to ensure quality from multiple aspects such as raw material selection, process control, equipment maintenance, and quality inspectionPET gold-plated filmUniformity and consistency.

Raw material selection

1. Selection of PET substrate

-

High purity: Choose PET substrates with high purity to reduce the impact of impurities on the coating.

-

Uniform thickness: Ensure that the thickness of the PET substrate is uniform and consistent, avoiding uneven coating thickness caused by uneven substrate thickness.

-

Surface treatment: Proper surface treatment of PET substrate, such as cleaning, pretreatment, etc., to improve the adhesion and uniformity of the coating.

2. Selection of gold plating materials

-

High purity: Choose high-purity gold materials, such as 99.99% pure gold, to ensure the conductivity and corrosion resistance of the coating.

-

Uniform particle size: Choose gold powder or gold solution with uniform particle size to avoid uneven coating caused by uneven particle size.

-

Good stability: Choose chemically stable and non oxidizing gold materials to ensure the quality of the coating.

process control

1. Cleaning and pre-treatment

-

Cleaning: Thoroughly clean the PET substrate before gold plating to remove surface impurities such as oil and dust.

-

Pre treatment: Pre treatment of PET substrate, such as activation, roughening, etc., to improve the adhesion and uniformity of the coating.

2. Gold plating method

-

Vacuum evaporation: Deposition of a gold layer on PET substrate by vacuum evaporation method to ensure the uniformity and density of the coating.

-

Chemical plating: Using chemical gold plating method, a gold layer is formed on PET substrate through chemical reaction, which is simple to operate and has low cost.

-

Electroplating: Deposition of gold layer on PET substrate by electroplating method, suitable for large-scale production, but requires strict control of current density and electroplating time.

3. Temperature and time control

-

Temperature control: Strictly control the temperature during the gold plating process to avoid excessive or insufficient temperature affecting the uniformity and quality of the coating.

-

Time control: Reasonably control the gold plating time to ensure uniform and consistent coating thickness.

4. Atmosphere control

-

Inert atmosphere: During the gold plating process, an inert gas (such as nitrogen) is used for protection to prevent oxidation of the gold layer and ensure the uniformity and quality of the coating.

Equipment maintenance

1. Regular inspection and maintenance

-

Equipment inspection: Regularly check the operating status of gold-plated equipment to ensure its normal operation.

-

Cleaning and maintenance: Regularly clean equipment, especially key components such as nozzles and spray heads, to avoid blockages and contamination.

2. Calibration and Calibration

-

Calibration: Regularly calibrate the temperature, pressure, flow rate and other parameters of the gold plating equipment to ensure accurate measurement.

-

Calibration: Regularly calibrate the performance of gold plating equipment to ensure that it meets production process requirements.

Quality inspection

1. Online detection

-

Thickness detection: Use an online thickness gauge to detect the thickness of the coating in real time, ensuring that the coating is uniform and consistent.

-

Appearance inspection: Use high-precision cameras or microscopes to inspect the appearance quality of the coating, promptly detect and handle defects.

2. Offline detection

-

Conductivity testing: Use a four probe method or resistance tester to test the conductivity of the coating to ensure it meets the requirements.

-

Adhesion testing: Use the scratch method or peel test to test the adhesion of the coating, ensuring its firmness and reliability.

-

Corrosion resistance testing: The corrosion resistance of the coating is tested through salt spray test or wet heat test to ensure its stability in harsh environments.

conclusion

Ensuring the uniformity and consistency of PET gold plating film during the manufacturing process requires starting from multiple aspects such as raw material selection, process control, equipment maintenance, and quality inspection. By comprehensively considering these factors and taking corresponding measures, the quality and production efficiency of PET gold plating film can be effectively improved. With the continuous advancement of technology, we will continue to conduct in-depth research and promote the continuous development and innovation of PET gold plating film manufacturing technology in the future.

The above data is for reference only, and specific performance may vary due to production processes and product specifications.