Hotline:0755-22277778

Tel:0755-22277778

Mobile:13826586185(Mr.Duan)

Fax:0755-22277776

E-mail:duanlian@xianjinyuan.cn

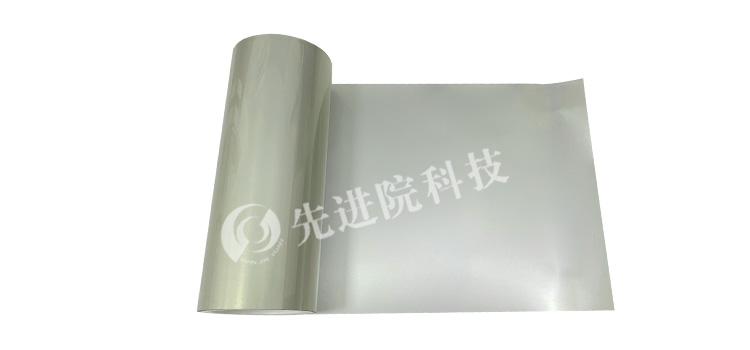

With the rapid development of the electronics industry,Polyimide (PI) tin plated filmDue to its excellent heat resistance and conductivity, it has been widely used in flexible circuit boards (FPCs), connectors in high-temperature environments, and other high-performance electronic products. This article will provide a detailed introduction on how to test the conductivity of PI tin plated film and demonstrate its performance under different conditions through experimental data.

Testing the conductivity of PI tin plated film is to ensure that the material can meet the conductivity requirements in specific applications. The quality of conductivity directly affects the reliability and service life of the product. Therefore, accurate assessmentPI tin plated filmThe conductivity is crucial for product quality control.

The four probe method is a commonly used and accurate method for measuring thin layer resistance. This method calculates the conductivity by measuring the resistivity of the material using four probes. Among the four probes, two are used to inject current, and the other two are used to detect voltage drop. This method can effectively eliminate the influence of contact resistance.

A multimeter is also a commonly used resistance measuring tool. Although not as accurate as the four probe method, it is still very useful for preliminary evaluation of the conductivity of PI tin plated film. When using a multimeter, it is necessary to ensure good contact between the measuring electrode and the surface of the tin plated film, and record data from multiple locations to ensure the accuracy of the measurement results.

This experiment is conducted inAdvanced Institute (Shenzhen) Technology Co., LtdConducted in the laboratory. Two different thicknesses of PI tin plated film samples were selected for the experiment, namely Group A (5 μ m tin layer) and Group B (10 μ m tin layer). The experimental environment temperature is 25 ° C ± 2 ° C, and the relative humidity is 50% ± 5%.

The average resistance value of Group A samples measured by the four probe method is 0.05 Ω/sq, while the average resistance value of Group B samples is 0.03 Ω/sq. The results obtained using a multimeter are similar, with an average resistance value of 0.051 Ω/sq for sample A and 0.032 Ω/sq for sample B.

From the comparison of data, as the thickness of the tin plating layer increases,PI tin plated filmThe conductivity is significantly enhanced. This indicates that, all other conditions being equal, the thickness of the tin plating layer is an important factor affecting conductivity.

The experimental results indicate that the conductivity of PI tin plated film is closely related to the thickness of the tin plating layer. A thicker tin plating layer can not only improve conductivity, but also enhance its mechanical strength and corrosion resistance. This is particularly important for electronic components that need to work in harsh environments.

We verified the performance differences of PI tin plated film under different tin plating layer thicknesses through conductivity testing. The experimental data clearly demonstrates the effect of tin plating thickness on conductivity. In the future, when developing new PI tin plated films, the process of tin plating can be further optimized to meet higher performance requirements.

The above data is for reference only, and specific performance may vary due to production processes and product specifications.

Advanced Institute (Shenzhen) Technology Co., Ltd, © two thousand and twenty-onewww.leird.cn. All rights reservedGuangdong ICP No. 2021051947-1 © two thousand and twenty-onewww.xianjinyuan.cn. All rights reservedGuangdong ICP No. 2021051947-2