Hotline:0755-22277778

Tel:0755-22277778

Mobile:13826586185(Mr.Duan)

Fax:0755-22277776

E-mail:duanlian@xianjinyuan.cn

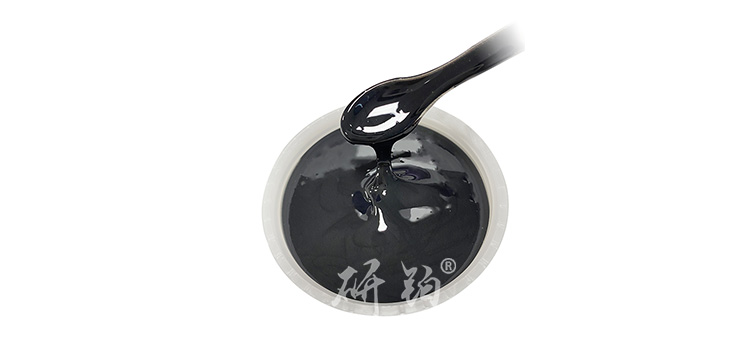

Platinum conductor paste plays an important role in many electronic and electrical applications, but it is not always an ideal choice. This article will focus onResearch Platinum Brand YB8206 Platinum Conductor PasteFor example, based on relevant research and experimental data from Advanced Institute (Shenzhen) Technology Co., Ltd., this paper explores under what circumstances platinum conductor paste is not suitable for use and proposes improvement suggestions.

Advanced Institute (Shenzhen) Technology Co., Ltd. conducted a comparative experiment by placing the YB8206 platinum conductor paste of Yanbo brand and another metal paste with good high-temperature oxidation resistance (labeled as paste A) in a high-temperature oxidation environment. The experimental temperature is set at 800 ° C and the duration is 100 hours, conducted in an oxygen rich environment (with an oxygen content of 21%).

In this high-temperature oxidation environment,Research Platinum Brand YB8206 Platinum Conductor PasteThe performance degradation is quite obvious, especially the significant decrease in conductivity. For some high-temperature electronic devices that require high conductivity stability, such as high-temperature sensor circuits in aerospace engines, this platinum conductor paste may not be suitable for use.

Advanced Institute (Shenzhen) Technology Co., LtdDesigned an experimental chamber that simulates a high humidity and high salt spray environment. Place the YB8206 platinum conductor paste and a precious metal mixed paste with good corrosion resistance (marked as paste B) in it. The experimental environment is set to a relative humidity of 95%, a salt spray concentration of 5% (mass fraction), and a duration of 500 hours.

In high humidity and high salt spray environments, the adhesion of YB8206 platinum conductor paste from Yanbo brand decreases significantly. This may not be a suitable choice for electronic circuits that need to maintain structural stability in such harsh environments for a long time, such as ocean monitoring equipment circuits at the seaside.

Advanced Institute (Shenzhen) Technology Co., Ltd. has built a high-frequency alternating electric field testing platform. Research on YB8206 platinum conductor paste with a specialized material for high-frequency circuitsSilver based conductor paste(marked as slurry C) for comparative experiments. Set the frequency of the alternating electric field to 10GHz and apply the electric field continuously for 10 hours.

In a high-frequency alternating electric field environment,Research Platinum Brand YB8206 Platinum Conductor PasteThe increase in dielectric loss is significant, which may not be suitable for applications such as high-frequency communication circuits that require strict dielectric performance, such as certain high-frequency circuit components in 5G communication base stations. This platinum conductor paste may not be suitable for use.

In addition to the aforementioned environments,Platinum conductor pasteIt may also exhibit different characteristics in extreme low temperatures, strong radiation, and strong acid-base environments. For example, at extremely low temperatures, platinum conductor paste may become brittle and increase, affecting its mechanical properties; In a strong radiation environment, radiation damage may occur, affecting its conductivity; In strong acidic and alkaline environments, chemical corrosion may occur, leading to a decrease in its performance.

Therefore, when using the YB8206 platinum conductor paste from Yanbo brand in these special environments, special attention should be paid to its applicability and potential risks.

The following improvement measures can be taken to address the issues mentioned above:

In summary, through the comparison of various experimental data from Advanced Institute (Shenzhen) Technology Co., Ltd., it is known that the YB8206 platinum conductor paste of Yanbo brand has problems such as decreased conductivity, decreased adhesion, and increased dielectric loss in high-temperature oxidation environment, high humidity and high salt spray environment, high-frequency alternating electric field environment, and other extreme environments. In these specific application scenarios that require high performance, careful consideration should be given to their applicability, and other more suitable slurries may need to be selected to meet engineering requirements. Meanwhile, through material modification, process optimization, and environmental adaptability design, the performance of platinum conductor paste can be further improved, making it better suited for various complex environments.

The above data is for reference only, and specific performance may vary due to production processes and product specifications.

Advanced Institute (Shenzhen) Technology Co., Ltd, © two thousand and twenty-onewww.leird.cn. All rights reservedGuangdong ICP No. 2021051947-1 © two thousand and twenty-onewww.xianjinyuan.cn. All rights reservedGuangdong ICP No. 2021051947-2