Hotline:0755-22277778

Tel:0755-22277778

Mobile:13826586185(Mr.Duan)

Fax:0755-22277776

E-mail:duanlian@xianjinyuan.cn

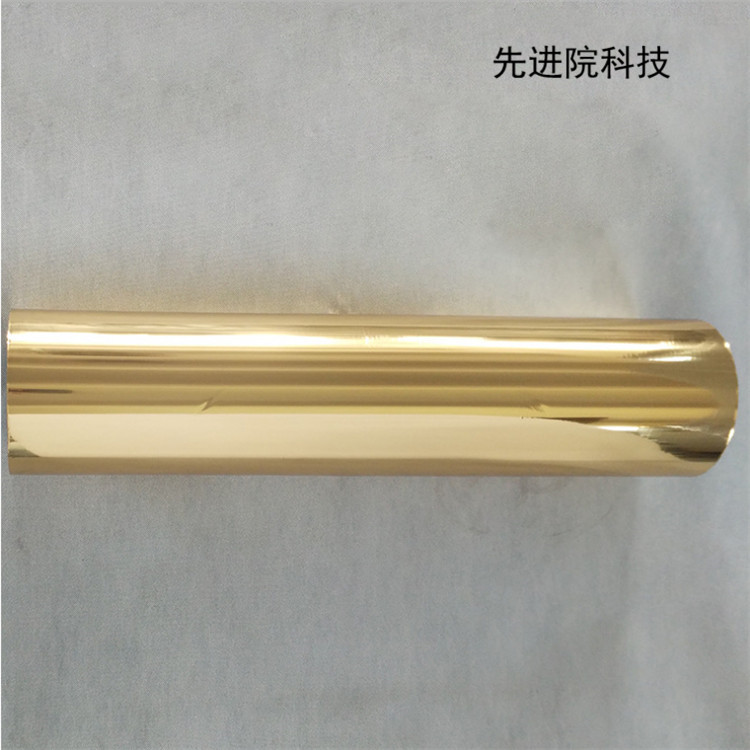

Advanced Institute of TechnologyDouble sided gold-plated copper foilGenerally, nickel plating is first followed by gold plating, and there are requirements for the thickness of nickel based gold plating. Generally, the thicker the plating, the more expensive it is. Huawei 5G signal reception now has high requirements. Many customers choose gold-plated copper foil by first chemically treating the surface of the copper foil with a layer of metallic nickel, and then electroplating a layer of gold on its surface to make it have good surface conductivity, which can improve the shielding efficiency to over 90dB in a wide frequency range.

The exposed copper foil on the surface of electrolytic copper foil used for PCB is prone to oxidation in the air, which can cause the PCB copper foil pads to not be soldered, poor soldering, or poor electrical performance contact, reducing product performance and even causing product failure. Therefore, it is necessary to add surface treatment to the PCB copper foil for protection, and immersion gold and gold plating are two common surface treatment methods. Copper foil gold deposition is a method of forming a gold coating on copper foil through chemical deposition, which enhances the oxidation resistance of PCB pads, strengthens solderability, and also extends the shelf life of PCB.Copper foil gold platingUsually refers to electroplated gold, which is achieved by plating copper foil with gold (such as gold finger gold plating) to enhance PCB wear resistance, oxygen resistance, and contact reliability.

Quality requirements and specifications:

| Product model |

XJY-25 |

| type |

Gold-plated copper foil |

| Main materials |

Copper foil, nickel layer, gold layer |

| Basic thickness |

25±3um |

| Plane resistance (Ω/⊙) |

<0.01 |

| width |

500mm |

| Shielding effectiveness |

>90dB |

Product application: The gold plating layer has high chemical stability, low contact resistance, good conductivity, easy soldering, strong corrosion resistance, and therefore has a wide range of applications in precision instruments, mobile electronics, printed circuit boards, integrated circuits, casings, electrical contacts, and other fields.

If you need this product or would like to learn more about related issues or product information, please contact us. We will solve your problems and provide services:

Advanced Institute (Shenzhen) Technology Co., Ltd, © two thousand and twenty-onewww.leird.cn. All rights reservedGuangdong ICP No. 2021051947-1 © two thousand and twenty-onewww.xianjinyuan.cn. All rights reservedGuangdong ICP No. 2021051947-2