Hotline:0755-22277778

Tel:0755-22277778

Mobile:13826586185(Mr.Duan)

Fax:0755-22277776

E-mail:duanlian@xianjinyuan.cn

Platinum paste is a special material widely used in different fields. It plays an important role as an electrode material in fields such as electronic products and automotive parts. However, do you know any secrets hidden in the preparation process of platinum paste? This article will take you on a glimpsePlatinum electrode slurryThe mysterious veil reveals its mysteries.

1. The magical process of preparing platinum slurry

Every high-quality platinum paste product undergoes a meticulous and complex preparation process.Advanced Institute Technology CompanyWe have collaborated with Jiangsu Automotive Parts Company to conduct extensive research and development in order to produce high-quality platinum paste. During this process, they discovered a mysterious preparation method that made platinum slurry unique.

2. Platinum slurry is fired into a non porous state

preparationPlatinum electrode slurryOne of the key factors is the sintering process. The platinum slurry prepared by traditional sintering process may have some pores, which reduces its effectiveness. However, the process developed in collaboration between Advanced Institute Technology Company and Jiangsu Automotive Parts Company can form a pore free platinum slurry during sintering, greatly improving its conductivity and stability.

3. Dry film recommended 8-12um, wet film 18-22um

The film thickness of platinum slurry has a direct impact on its performance. After extensive experimentation and research, Advanced Institute Technology Company and Jiangsu Automotive Parts Company recommend a dry film thickness of 8-12um and a wet film thickness of 18-22um. This film thickness can enhance the conductivity and durability of platinum paste during use.

4. The viscosity test conditions are BROOK Field DV-II, 52 ", 1rpm, 25 ℃

The viscosity of the slurry is one of the important indicators of its performance. In order to ensure the quality of the platinum paste meets the requirements, Advanced Institute Technology Company and Jiangsu Automotive Parts Company have adopted the viscosity testing standard: BROOK Field DV-II, 52 ", 1rpm, 25 ℃. Through rigorous testing, the viscosity stability and usability of the platinum slurry have been ensured.

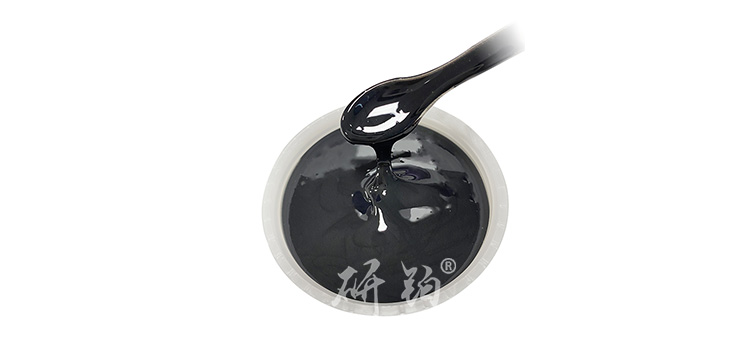

5. Appearance of Platinum Slurry

The appearance of high-quality platinum paste presents a uniform gray black color. Through advanced preparation technology and precise formula control, Advanced Institute Technology Company and Jiangsu Automotive Parts Company producePlatinum pasteThe appearance has a high degree of consistency, which not only meets the product requirements, but also brings users a good visual experience.

Summary: The preparation process of platinum electrode slurry contains many hidden secrets. The cooperation between Advanced Institute Technology Company and Jiangsu Automotive Parts Company in research and development has enabled platinum paste to form a non porous state during the preparation process, improving conductivity and stability. Meanwhile, strict film thickness recommendations and viscosity testing conditions ensure the quality stability of the product. The appearance and color of platinum paste are uniform, giving people a good visual experience. Through the revelation of these secrets, we have gained a deeper understanding of the characteristics and preparation process of platinum electrode slurries, as well as a more comprehensive understanding of their application fields.

Advanced Institute (Shenzhen) Technology Co., Ltd, © two thousand and twenty-onewww.leird.cn. All rights reservedGuangdong ICP No. 2021051947-1 © two thousand and twenty-onewww.xianjinyuan.cn. All rights reservedGuangdong ICP No. 2021051947-2