Hotline:0755-22277778

Tel:0755-22277778

Mobile:13826586185(Mr.Duan)

Fax:0755-22277776

E-mail:duanlian@xianjinyuan.cn

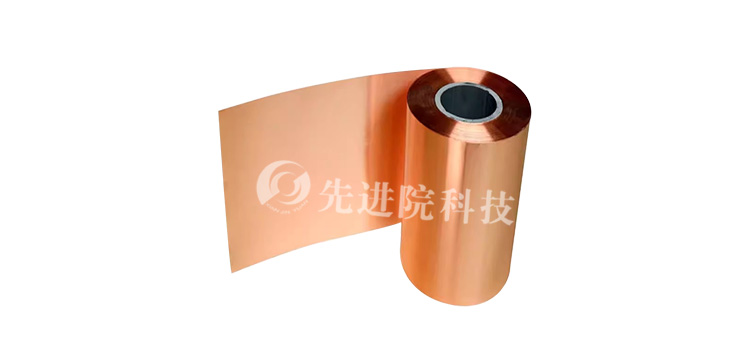

With the continuous development of technology, new materials are being applied more and more widely in various fields. Among them, 4.5 μ mPET film coated with double-sided copperAlso known as PET copper foil, as a brilliant innovation, it is rapidly surpassing people's imagination. Advanced Institute Technology will introduce the characteristics of PET copper foil and its application in the field of lithium batteries, taking you to appreciate the charm of technology.

1. PET copper foil: a thin and powerful lithium battery material

Innovative material: PET copper foil is a composite copper foil composed of 4.5 μ m PET films coated with 1 μ m copper on both sides, with a total thickness of 6.5 μ m. This design allows PET copper foil to have thinner thickness and smaller copper usage, making it shine in the field of lithium batteries.

High performance:PET copper foilThe use of polymer based material PET instead of traditional metal copper has the characteristics of low density, low Young's modulus, and high compressibility. These features effectively enhance the safety and energy density of lithium batteries, bringing new possibilities for the development of the lithium battery industry.

2. Differences between PET copper foil and traditional copper foil

Production process: Traditional copper foil is mainly prepared by electrolysis, while PET copper foil is prepared by new processes such as vacuum coating and ion exchange. The introduction of this process makes PET copper foil more environmentally friendly and can improve production efficiency in the production process. PET copper foil has attracted much attention due to its innovative manufacturing process.

Material characteristics: PET copper foil is thinner compared to traditional copper foil, which makes it more flexible in the application of lithium batteries. Meanwhile,PET copper foilThe material properties of the material make it have better stress resistance and tear resistance, which improves the service life and safety of lithium batteries.

3. The application value of PET copper foil in the field of lithium batteries

Improving safety: PET copper foil, as a heat sink and connector for lithium batteries, has high temperature resistance and corrosion resistance, which helps to enhance the safety of lithium batteries and avoid thermal runaway caused by excessive temperature.

Improving energy density: The thin thickness and low copper usage of PET copper foil enable lithium batteries to store more electrical energy while maintaining a smaller volume, increasing the energy density of lithium batteries and meeting people's demand for mobile power sources.

Promoting industry development: With the rapid development of the lithium battery industry, the requirements for high performance and high safety are also increasing. The introduction of PET copper foil provides a new solution for the lithium battery industry, which is expected to promote the development of the entire industry towards a more environmentally friendly and efficient direction.

Summary: Through 4.5 μ mPET film coated with double-sided copperThe innovative application of PET copper foil has made the outlook for safety and energy density in the lithium battery industry more optimistic. With the continuous advancement of technology, it is believed that the application prospects of PET copper foil in the field of lithium batteries will become increasingly broad. In the future, we may see more innovative materials emerging in this field, bringing more possibilities for the development of battery technology. Let's wait and see, looking forward to the lithium battery industry reaching new heights.

Advanced Institute (Shenzhen) Technology Co., Ltd, © two thousand and twenty-onewww.leird.cn. All rights reservedGuangdong ICP No. 2021051947-1 © two thousand and twenty-onewww.xianjinyuan.cn. All rights reservedGuangdong ICP No. 2021051947-2