Hotline:0755-22277778

Tel:0755-22277778

Mobile:13826586185(Mr.Duan)

Fax:0755-22277776

E-mail:duanlian@xianjinyuan.cn

Reflective film is a type of reflective layer used on the surface of electronic products, typically composed of an ultra-thin PET (polyester) substrate and a silver reflective layer. The main function of reflective film is to improve the appearance and performance of electronic product surfaces, while also protecting the surface of electronic products from damage. Reflective films are widely used in various electronic products, such as mobile phones, tablets, TV screens, etc.

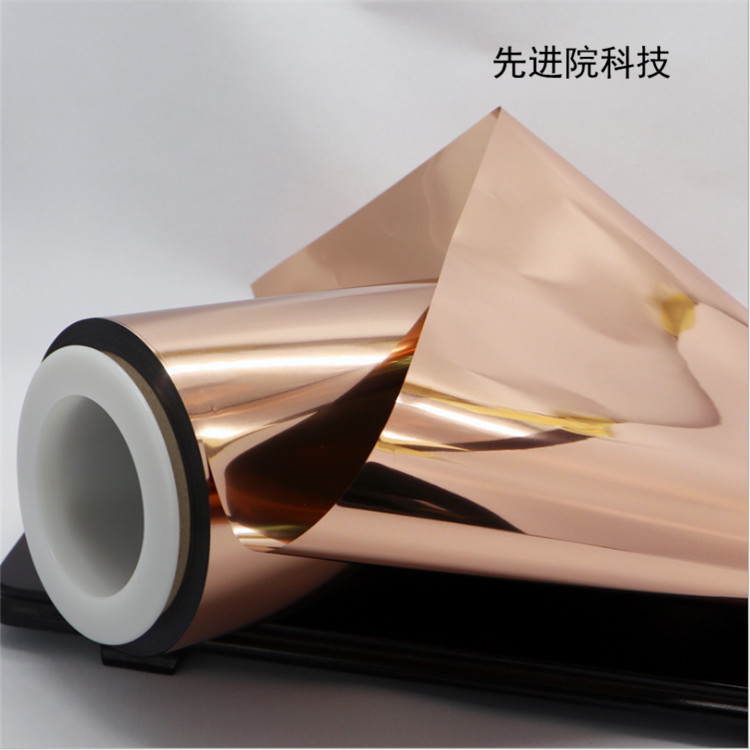

Advanced Institute of TechnologyUltra thin single-sided silver reflective filmHigh reflectivity of over 98%, material thickness of 0.045MM, suitable for lighting fixtures, backlight sources, natural light reflection, various types of ray reflection, sensor device reflection (especially suitable for the design and production of ultra-thin products such as backlight sources). Silver reflective film, with a multi-layer film structure made of PET resin as raw material, is an optical thin film with very high reflectivity in the visible light wavelength range. Can be used as a reflective film under the backlight light guide plate, with minimal light loss during reflection. By effectively utilizing the light emitted by the light source, the brightness of the image can be improved.

Reflective films are widely used in liquid crystal display devices, lighting instruments, lighting advertisements, etc. Among them, reflective films are mostly smooth flat surfaces. Although they can reflect light, this single smooth flat reflective film will cause a decrease in brightness due to the loss of reflected light in the mirror surface during use. At the same time, due to the poor heat resistance of a single smooth flat reflective film during use, it is easy to deform and cause the reflective film to curl up, leading to the occurrence of shadow phenomenon. In order to solve the problem of specular reflection light loss, many manufacturers reduce specular reflection by coating transparent convex layers on the reflective film. However, this approach has the disadvantage of unsustainable powdering and peeling. At the same time, manufacturing reflective films through this method also increases the manufacturing cost of reflective films.

In order to solve the above problems, some manufacturers also produce white reflective films through conventional three roll rolling in existing reflective films, reflective sheets, or reflective covers, and add a raised layer on the reflective surface of the reflective film to improve the reflection brightness. However, this structure of reflective film contains a high concentration of inorganic reflective particles, resulting in a heavy proportion of reflective film, which is not conducive to the lightweighting of large-sized display screens and components. Moreover, the reflective film is prone to oxidation discoloration under high-temperature operating conditions for a long time, which affects the surface structure of the reflective film and reduces its optical performance.

If you need this product or would like to learn more about related issues or product information, please contact us. We will solve your problems and provide services:

Advanced Institute (Shenzhen) Technology Co., Ltd, © two thousand and twenty-onewww.leird.cn. All rights reservedGuangdong ICP No. 2021051947-1 © two thousand and twenty-onewww.xianjinyuan.cn. All rights reservedGuangdong ICP No. 2021051947-2