Hotline:0755-22277778

Tel:0755-22277778

Mobile:13826586185(Mr.Duan)

Fax:0755-22277776

E-mail:duanlian@xianjinyuan.cn

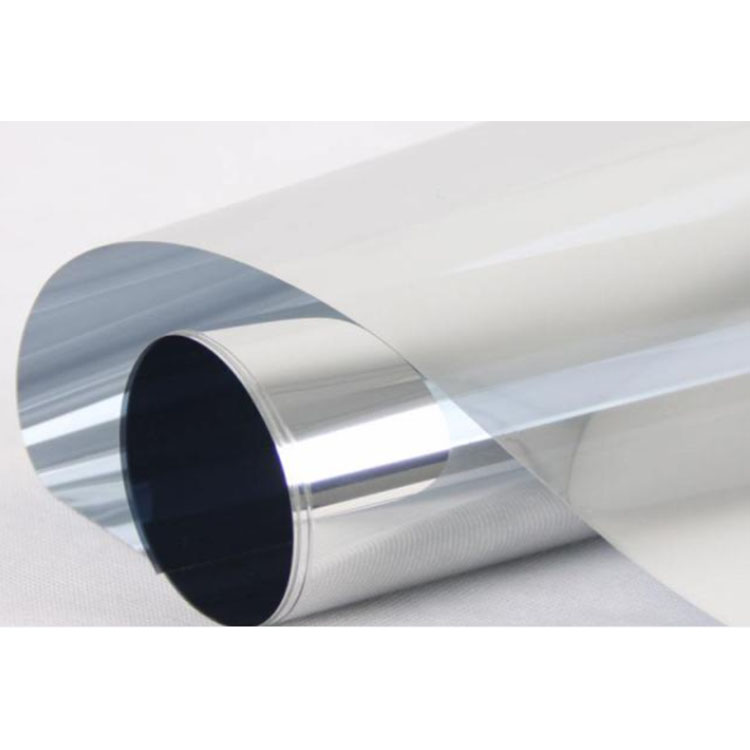

PET film is a high-performance plastic film widely used in packaging, construction, electronics and other fields. In the production process of PET film, aluminum coated PET film is a common variant, which has good shielding effect and good appearance performance, and is widely used in industries such as food, medicine, cosmetics, etc.

In the early stages of PET film manufacturing, traditional manufacturing methods used a two-layer structure, namely PET substrate and aluminum foil. Although this manufacturing method has a high shielding effect, it has some drawbacks. For example, the processing of aluminum foil is difficult, costly, and prone to oxidation and contamination, which affects the quality of the product. Therefore, people began to seek a more efficient manufacturing method.

The modern PET film manufacturing process adopts a single-layer structure, that is, aluminum foil is directly plated on the surface of PET substrate to achieve better performance and lower cost. This manufacturing method is achieved through physical vapor deposition (PVD) and chemical vapor deposition (CVD) techniques. Among them, PVD is the process of heating aluminum foil to high temperature, evaporating it into gaseous aluminum, and then depositing a coating on the surface of PET substrate. CVD generates metallic aluminum by reacting on the surface of PET substrate, forming a coating.

In addition to innovation in manufacturing processes, there are also some technological innovations that play a crucial role in PET film manufacturing. For example, polymer chemical modification technology can improve the tensile strength and impact resistance of PET films, thereby better meeting the needs of various application scenarios. At the same time, nanotechnology can be used to form nanostructures on the surface of PET films, thereby improving their antibacterial and pollution resistance properties.

Aluminum coated PET film is a composite material with excellent barrier properties and decorative effects, which is made by coating a layer of aluminum film on the surface of PET film. Aluminum coated PET film has good heat resistance, moisture resistance, chemical resistance, and mechanical properties, and can be widely used in packaging fields such as food, medicine, electronics, cosmetics, and other industries. In addition, aluminum coated PET film can also be used to produce high-tech products such as insulation materials, capacitors, and solar cells.

As a variant of PET film, aluminum coated PET film has the following advantages:

Excellent shielding performance: The aluminum layer has good electromagnetic wave shielding performance, which can effectively prevent external radiation from interfering with internal products, such as high-frequency electromagnetic waves, radio frequency signals, etc.

Good high temperature resistance: Due to the high melting point of aluminum, aluminum coated PET film has excellent high temperature resistance and can be used in high temperature environments.

Good appearance effect: Aluminum plated PET film has good metallic luster and reflective performance, with a beautiful appearance effect, suitable for high-end products in various packaging and printing industries.

Good moisture resistance: PET substrate itself has good moisture resistance, coupled with the moisture and oxygen barrier properties of aluminum layer, it can better protect internal products from moisture, oxidation, pollution and other influences.

Lightweight and easy to form: Compared to traditional PET substrates and aluminum foil composites, aluminum coated PET films only have a thin layer of aluminum coated on the surface of the PET substrate, making them lighter in weight and easier to form.

If you need this product or would like to learn more about related issues or product information, please contact us. We will solve your problems and provide services:

Advanced Institute (Shenzhen) Technology Co., Ltd, © two thousand and twenty-onewww.leird.cn. All rights reservedGuangdong ICP No. 2021051947-1 © two thousand and twenty-onewww.xianjinyuan.cn. All rights reservedGuangdong ICP No. 2021051947-2