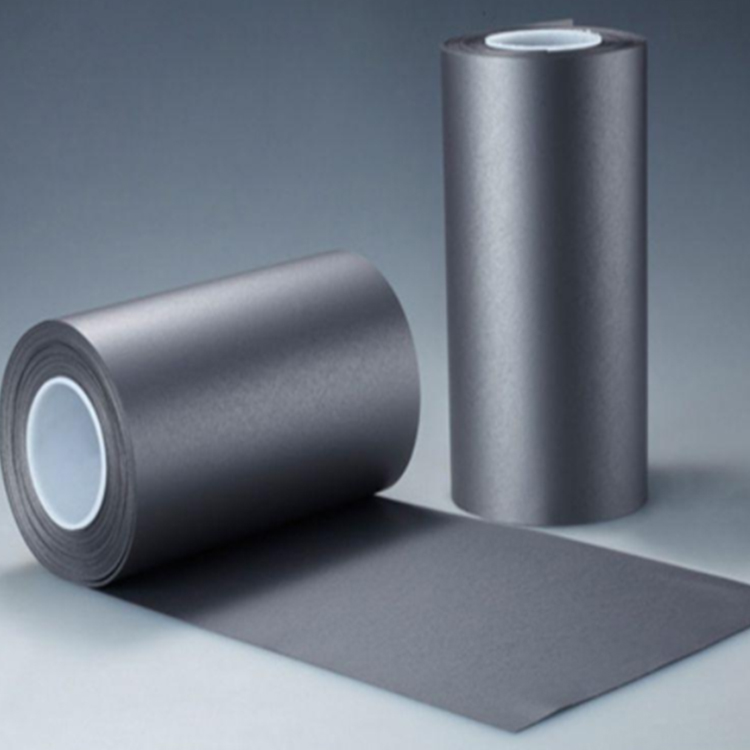

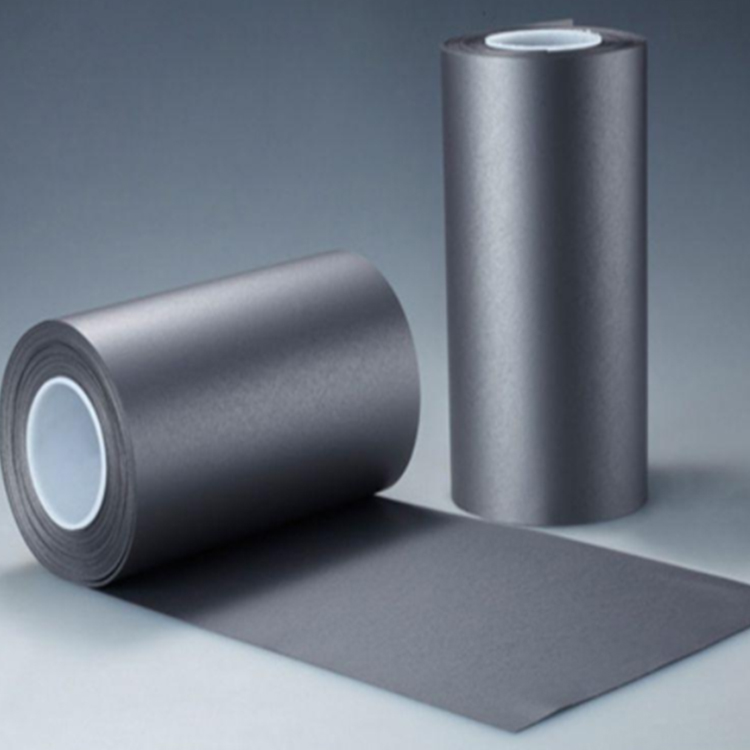

EMI absorbing materialIt is a material that can effectively block electromagnetic interference (EMI) signals and has a wide range of applications. It plays an important role in industries such as electronic device manufacturing, communication systems, aerospace, and military. This article will provide a detailed introduction to the basic principles, classification, and application scenarios of EMI absorbing materials.

1、 Basic principles of EMI absorbing materials

The basic principle of EMI absorbing materials is to use special material structures and properties to absorb EMI interference signals generated by external environments or internal circuits, and convert them into weak thermal energy or other forms of energy to dissipate. This can ensure that electronic devices work properly and are not affected by EMI signals.

There are three main absorption mechanisms of EMI absorbing materials:

Reflective absorptionResonance type absorption and impedance matching type absorption. Among them, reflective absorption is the most common type. When the EMI signal reaches the surface of the EMI absorbing material, due to the complex reflection coefficient of the material surface, some of the signal will be reflected back, while the remaining signal will pass through the material and enter the interior of the material. Then, due to the complex structure and properties inside the material, the signal will continuously reflect, attenuate, scatter, and transform, ultimately being completely absorbed or weakened.

2、 Classification of EMI absorbing materials

The classification of EMI absorbing materials is mainly based on their properties, morphology, and other aspects. Common EMI absorbing materials include: metal powder filled type, magnetic absorbing type, carbon based conductive polymer, composite absorbing type, etc.

1. Metal powder filling type

Metal powder filled EMI absorbing materialIt is a composite material composed of metal particles and polymer matrix. Metal particles are usually made of ferromagnetic materials such as iron, nickel, cobalt, or conductive materials such as copper and silver. The absorption mechanism of this material mainly relies on the conductivity and magnetic properties of metal particles, which continuously reflect, attenuate, scatter, and convert EMI signals inside the material, thereby achieving effective absorption effect.

2. Magnetic absorption type

Magnetic absorbing EMI absorbing material is a material that utilizes the hysteresis loss and magnetic permeability changes of magnetic materials to achieve absorption effect. Common magnetic materials include ferrite, soft magnetic alloys, etc. The absorption mechanism of this material is mainly through the hysteresis loss and magnetic permeability change of magnetic materials, which convert EMI signals into weak thermal energy or other forms of energy and dissipate them.

3. Carbon based conductive polymer

Carbon based conductive polymer EMI absorbing material is a material that utilizes the conductivity and absorption of carbonaceous materials such as carbon nanotubes, graphene, and carbon black to achieve absorption effects. such

The absorption mechanism of materials mainly relies on the conductivity and magnetic permeability of carbonaceous materials, which cause energy loss and scattering of EMI signals inside the material, thereby achieving effective absorption effect.

4. Composite absorbing type

Composite absorbing EMI absorbing material is a composite material composed of multiple absorbing materials. The absorption mechanism of this material mainly relies on the interaction and synergistic effect between different materials to achieve a wider range of absorption frequency bands and higher absorption efficiency. common

Composite absorbing materialIncluding metal powder magnetic material composites, carbon based conductive polymer magnetic material composites, etc.

3、 Application scenarios of EMI absorbing materials

EMI absorbing materials have a wide range of application fields, mainly including the following aspects:

1. Manufacturing of electronic devices

In the electronic device manufacturing industry, EMI absorbing materials can be used for EMI shielding and interference protection of electronic components, circuit boards, chassis, and other parts. For example, in devices such as mobile phones, tablets, laptops, etc., metal powder filled or carbon based conductive polymer EMI absorbing materials are commonly used to suppress EMI interference inside and outside the device.

2. Communication system

In communication systems, EMI absorbing materials can be used for EMI shielding and interference protection of components such as antennas, RF modules, and transmission lines. For example, in wireless communication base stations, satellite communication terminals, and other equipment, magnetic absorbing or composite absorbing EMI absorbing materials are commonly used to ensure signal transmission quality and stability.

3. Aerospace

In the aerospace field, EMI absorbing materials can be used for EMI shielding and interference protection of aircraft, rockets, satellites and other carriers. Due to the strict requirements for EMI interference in aerospace equipment, high-performance magnetic or composite EMI absorbing materials are often used.

4. Military field

In the military field,

EMI absorbing materialIt can be used for EMI shielding and interference protection of weapons and equipment such as radar, electronic countermeasures, and communication systems. Due to the strong decryption and interference resistance required for military equipment, high-performance composite absorbing materials or metal powder magnetic material composite EMI absorbing materials are often used.

Therefore, EMI absorbing materials are important electromagnetic interference protection materials with broad application prospects. With the continuous development of technology and the increasing requirements, EMI absorbing materials will be increasingly used in various fields, providing greater security for human work, life, and safety.