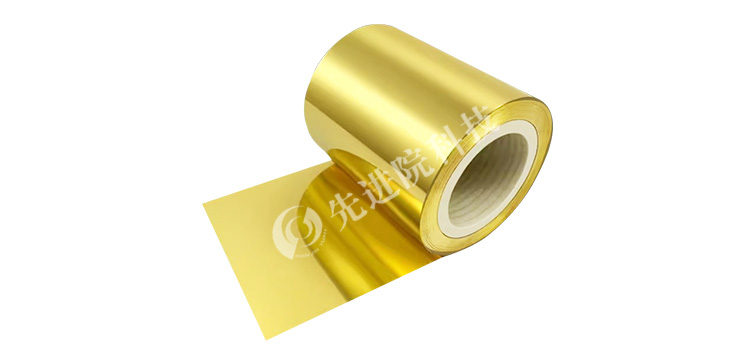

PET gold-plated reflective filmDue to its excellent optical reflection performance and lightweight characteristics, it has been widely used in aerospace, electronic devices, optical systems and other fields. However, in extreme temperature environments, the performance stability of PET gold-plated reflective films faces severe challenges. This article will explore the performance issues of PET gold-plated reflective film in high and low temperature environments, and propose corresponding solutions.

Structure and Properties of PET Gold Plated Reflective Film

The PET gold-plated reflective film consists of a PET substrate and a gold-plated layer. PET substrate has good mechanical properties and transparency, while the gold plating layer endows it with high reflectivity and low absorption. However, the thermal expansion coefficient of PET substrate is high, and the thermal stability of the gold plating layer is limited, which makes the reflective film prone to performance degradation in extreme temperature environments, such as decreased reflectivity and film peeling.

Performance Issues and Solutions in High Temperature Environments

Performance issues

Under high temperature conditions, the thermal expansion of PET substrate may cause an increase in stress between the gold plating layer and the substrate, leading to wrinkling or peeling of the gold plating layer. In addition, high temperature may accelerate the oxidation of the gold layer and reduce the reflectivity.

Solution

-

Substrate modification: By adding nano fillers (such as silica, carbon nanotubes, etc.) to PET substrates, the thermal expansion coefficient of the substrate can be effectively reduced, enhancing its thermal stability., Research has shown that adding an appropriate amount of nano fillers can reduce the thermal expansion coefficient of PET substrates by more than 30%.

-

Protective layer design: Adding a thin protective layer (such as silicon dioxide, aluminum nitride, etc.) on the surface of the gold plating layer can effectively block oxidation reactions at high temperatures and relieve stress between the substrate and the gold plating layer. The thickness of the protective layer is generally between 10-50 nanometers to ensure that the reflective performance is not affected.

-

Optimizing gold plating process: Advanced gold plating techniques such as ion beam plating or magnetron sputtering can be used to control the thickness and microstructure of the gold layer during the precise gold plating process, improving its high-temperature stability. In addition, by adjusting the gold plating process parameters such as temperature, air pressure, etc., the crystallinity and adhesion of the gold layer can be further optimized.

Performance issues and solutions in low-temperature environments

Performance issues

At low temperatures, the brittleness of PET substrates increases, which may lead to a decrease in the flexibility of the reflective film and even fracture. Meanwhile, low temperature may increase the internal stress of the gold plating layer, affecting its reflective performance.

Solution

-

Flexible substrate design: Developing PET substrates with excellent low-temperature toughness is the key to solving the problem of low-temperature performance. By introducing flexible segments (such as polyether segments) during the PET synthesis process, the low-temperature toughness of the substrate can be significantly improved. Experiments have shown that the fracture elongation of modified PET substrates can be increased by more than 50% at -60 ℃.

-

Gold plating optimization: using

Nano composite gold plating technologyComposite plating of gold with other metals (such as silver, copper, etc.) can maintain good reflective properties at low temperatures. The microstructure of the composite gold plating layer is denser and the internal stress distribution is more uniform, thereby improving its low-temperature stability.

-

Environmental adaptability testing and optimization: In the design and production process of reflective films, strict low-temperature environmental adaptability testing should be conducted, and material formulations and process parameters should be adjusted based on the test results. For example, by simulating the low-temperature conditions of the actual usage environment, repeated mechanical performance tests such as stretching and bending are conducted on the reflective film to ensure that it can maintain good performance in low-temperature environments.

conclusion

PET gold-plated reflective filmThe stability of its performance in high and low temperature environments is a key factor limiting its widespread application. Through measures such as substrate modification, protective layer design, gold plating process optimization, and flexible substrate development, the performance issues of PET gold plated reflective films in extreme temperature environments can be effectively addressed. In the future, with the continuous development of materials science and nanotechnology, the performance of PET gold-plated reflective film will be further improved, and it is expected to be widely applied in more fields.

The above data is for reference only, and specific performance may vary due to production processes and product specifications.