Hotline:0755-22277778

Tel:0755-22277778

Mobile:13826586185(Mr.Duan)

Fax:0755-22277776

E-mail:duanlian@xianjinyuan.cn

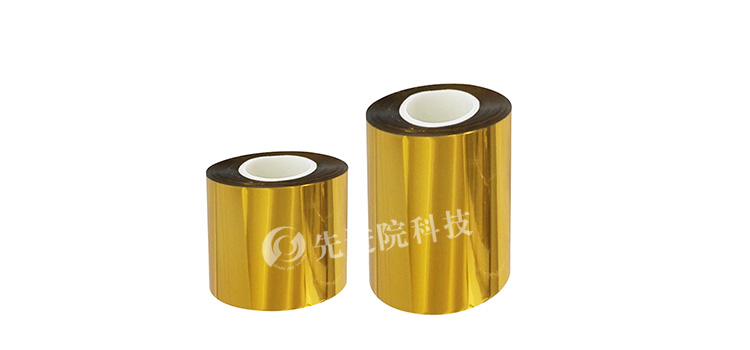

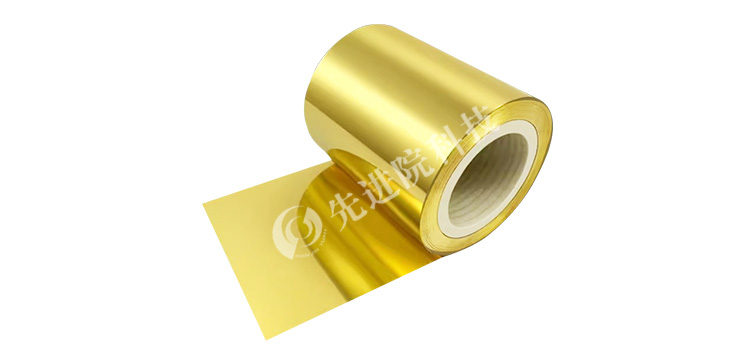

With the rapid development of fields such as electronics, optics, and packaging, the demand for high-performance and high value-added materials is increasing day by day. PP (polypropylene) gold plating film, as a composite material that combines the excellent physical properties of PP thin film with the high conductivity, high reflectivity, and high corrosion resistance of metallic gold, has shown wide application prospects in many fields. However, how to achieve uniform deposition of nano gold particles on the surface of PP film to obtain high-quality and high-performancePP gold-plated filmIt is currently a hot and difficult topic in research. This article will delve into the uniform deposition technology of nano gold particles on the surface of PP films and its influencing factors, providing theoretical basis and technical guidance for the preparation of PP gold plating films.

The preparation of nano gold particles is the first step in the preparation of PP gold plating film. Chemical reduction methods such as sodium citrate reduction and ascorbic acid reduction are commonly used to adjust the particle size and morphology of gold nanoparticles by controlling reaction conditions such as temperature, pH, and reaction time. The prepared nano gold particles need to be characterized, including particle size distribution, morphology, purity, etc., to ensure that they meet the requirements for subsequent deposition.

PP film asGold-plated filmThe surface properties of the substrate have a significant impact on the deposition effect of nano gold particles. Therefore, surface treatment of PP film is necessary before deposition to improve its surface energy, wettability, and roughness, thereby enhancing the bonding force between nano gold particles and PP film. Common surface treatment methods include plasma treatment, chemical etching, and primer coating.

There are various deposition techniques for nano gold particles on the surface of PP films, including electroplating, chemical plating, sputtering plating, etc. Among them, electroplating and chemical plating are widely used due to their simple operation and low cost. Electroplating can be achieved by controlling parameters such as current density and timeNano gold particlesUniform deposition on the surface of PP film; Chemical plating uses chemical reactions to reduce gold ions to gold atoms and deposit them on the surface of PP films. In order to obtain high-quality PP gold plating film, it is necessary to optimize the deposition technology, including selecting appropriate plating solution components, adjusting process parameters (such as temperature, pH value, current density, etc.), and controlling deposition time.

The particle size and distribution of nano gold particles are key factors affecting their uniform deposition on the surface of PP films. Excessive particle size or uneven distribution may increase the roughness of the deposited layer, affecting the smoothness and conductivity of the PP gold plating film. Therefore, it is necessary to control the particle size and distribution of nano gold particles to achieve the best deposition effect.

The surface properties of PP film, such as roughness, wettability, surface energy, etc., have a significant impact on the deposition effect of nano gold particles. PP films with higher roughness can increase the adhesion area of nano gold particles, improve the uniformity and adhesion of the deposited layer; PP films with good wetting properties contribute to the uniform dispersion and deposition of nano gold particles in the plating solution; PP films with higher surface energy can enhance the bonding force between nano gold particles and PP films.

The composition and process parameters of the plating solution have a significant impact on the uniform deposition of nano gold particles on the surface of PP films. The concentration of metal gold ions in the plating solution, the type and concentration of reducing agents, and the amount of stabilizers and surfactants added can all affect the deposition effect of nano gold particlesPP gold-plated filmThe performance. In addition, process parameters such as plating solution temperature, pH value, current density, etc. also need to be optimized to achieve the best deposition effect.

The treatment after deposition is also an important factor affecting the performance of PP gold plating film. This includes steps such as cleaning, drying, and curing to remove residual plating solution, improve the stability and adhesion of the gold plating layer. At the same time, post-treatment such as heat treatment, light treatment, etc. can be carried out on the PP gold plating film to further improve its performance.

The uniform deposition technology of nano gold particles on the surface of PP film is essential for preparing high-quality materialsPP gold-plated filmThe key. By controlling the preparation and characterization of nano gold particles, surface treatment of PP films, selecting appropriate deposition techniques and optimizing them, and controlling the treatment after deposition, uniform, dense, strong adhesion, and excellent performance PP gold plating films can be obtained. At the same time, it is necessary to conduct in-depth research on the influence of various influencing factors on the deposition effect and the performance of PP gold plating film, in order to provide a more comprehensive theoretical basis and technical guidance for the preparation of PP gold plating film. With the continuous progress and innovation of technology, it is believed that more efficient and environmentally friendly PP gold plating film preparation technologies will emerge in the future, injecting new vitality into the development of related fields.

The above data is for reference only, and specific performance may vary due to production processes and product specifications.

Advanced Institute (Shenzhen) Technology Co., Ltd, © two thousand and twenty-onewww.leird.cn. All rights reservedGuangdong ICP No. 2021051947-1 © two thousand and twenty-onewww.xianjinyuan.cn. All rights reservedGuangdong ICP No. 2021051947-2