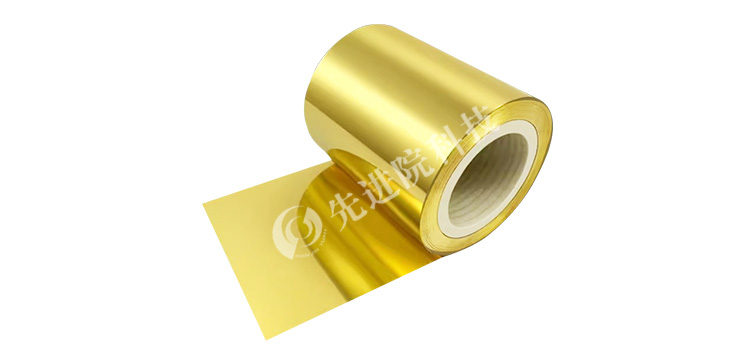

In the modern electronics industry,PI (Polyimide) Gold Plated FilmDue to its excellent conductivity, heat resistance, and chemical stability, it has become an ideal choice for connecting devices. However, during long-term use, the conductivity of PI gold plating film may be affected by various factors and deteriorate. This article will explore the reasons for this decline and propose effective preventive measures.

Reasons for the deterioration of conductivity of PI gold-plated film

-

Environmental factors:

-

Humidity and corrosion: A humid environment may cause electrochemical corrosion of the gold plating layer, thereby affecting its conductivity.

-

Temperature changes: Extreme temperature changes may cause thermal stress between the PI substrate and the gold plating layer, leading to microcracks or peeling of the coating.

-

Physical wear and tear:

-

Friction and Scratches: In long-term use and operation, the PI gold plating film may be subjected to friction and scratches, resulting in thinning or damage to the coating.

-

Chemical erosion:

-

Chemical contact: Some chemicals may react with the gold plating layer, causing a decrease in the performance of the coating.

preventive measure

-

Choose the appropriate coating process:

-

Magnetron Sputtering Gold Plating: Compared to electroplating processes, magnetron sputtering gold plating can deposit gold atoms more evenly, forming a dense and tightly structured coating that helps improve wear resistance and conductivity stability.

-

Optimize substrate surface treatment:

-

Thoroughly clean: Before coating, thoroughly clean the surface of the PI substrate to ensure that it is clean, smooth, and free of impurities such as grease and dust.

-

Surface pretreatment: Chemical oxidation, acid washing and other techniques are used to improve the activity and cleanliness of the PI substrate surface, enhance the adhesion and wear resistance of the coating.

-

Adjust the coating process parameters:

-

Optimize coating conditions: By adjusting parameters such as temperature, pressure, and time during the coating process, optimize the structure and performance of the coating. For example, appropriately increasing the coating temperature can promote the diffusion and bonding of gold atoms, improve the density and wear resistance of the coating.

-

Adopting multi-layer coating technology:

-

Transition metal layer: A layer of transition metal (such as nickel, chromium, etc.) is first plated on the PI substrate, followed by a gold plating layer to form a more complex coating structure, improving wear resistance and corrosion resistance.

-

Coating with wear-resistant coating:

-

Wear resistant coating: For application scenarios that require particularly high wear resistance, it can be used inPI gold-plated filmApply a layer of wear-resistant coating on the surface to improve the wear resistance and corrosion resistance of the coating.

-

New surface treatment technology:

-

Precise coating control: New surface treatment technologies such as atomic layer deposition (ALD) and molecular beam epitaxy (MBE) are used to achieve more precise coating control, further improving the wear resistance and conductivity stability of PI gold plating films.

-

Environmental Protection and Maintenance:

-

Environmental control: During the use and storage of electronic products, control the humidity and temperature of the environment to avoid the impact of extreme conditions on the PI gold plating film.

-

Regular inspection and maintenance: Regularly inspect and maintain electronic products to promptly identify and address any potential issues with the PI gold plating film.

conclusion

PI gold-plated filmDuring long-term use, its conductivity may be affected by various factors and deteriorate. However, by selecting appropriate coating processes, optimizing substrate surface treatment, adjusting coating process parameters, adopting multi-layer coating technology, applying wear-resistant coatings, and adopting new surface treatment technologies, we can effectively prevent the deterioration of the conductivity of PI gold plating films, extend the service life of electronic products, and improve their reliability and stability.

The above data is for reference only, and specific performance may vary due to production processes and product specifications.