Hotline:0755-22277778

Tel:0755-22277778

Mobile:13826586185(Mr.Duan)

Fax:0755-22277776

E-mail:duanlian@xianjinyuan.cn

Printing platinum pasteAs a high-performance electronic material, it plays an important role in sensor manufacturing, microelectronic packaging, and other fields due to its excellent conductivity, stability, and corrosion resistance. However, whether the performance of the material will degrade over time has become a focus of attention in the industry. This article will delve into the long-term stability and potential degradation mechanisms of printing platinum paste, with a particular focus on the research achievements and application practices of Advanced Institute (Shenzhen) Technology Co., Ltd. in this field.

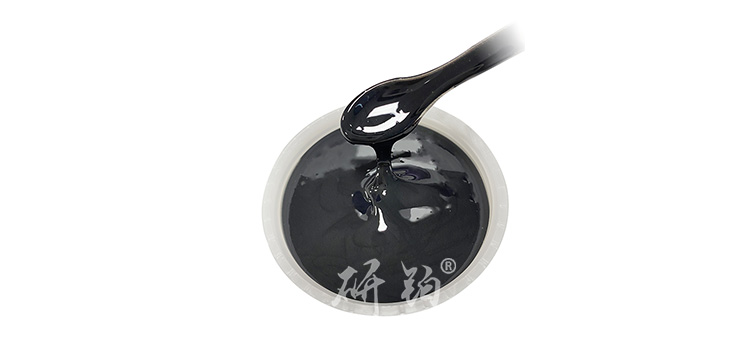

The printing platinum paste is mainly composed of platinum powder, glass binder, and carrier. Platinum powder, as the core component, endows the slurry with excellent chemical stability and high melting point characteristics, enabling it to maintain stable performance even in high temperature environments. Glass adhesive and carrier play a role in enhancing the adhesion and dispersibility of the slurry, ensuring that it can be uniformly and densely coated on the substrate during the printing process.

Platinum, as a rare and precious metal, has extremely strong chemical inertness. Therefore, during long-term use, printing platinum paste is not prone to chemical reactions with substances in the surrounding environment, thus maintaining its stability in performance.Advanced Institute (Shenzhen) Technology Co., LtdThrough strict material screening and process control, the chemical stability of platinum slurry has been further improved, ensuring its long-term reliability in harsh environments.

In terms of physical stability, printing platinum paste can still maintain structural integrity in harsh environments such as high temperature and high pressure. This is due to the high melting point characteristics of platinum powder and the reinforcing effect of glass binder and carrier. However, with the passage of time, the slurry may be affected by factors such as mechanical stress and thermal cycling, resulting in slight changes in the microstructure. Although these changes have little impact on performance in the short term, long-term accumulation may lead to performance degradation.

Environmental adaptability is one of the important indicators for measuring the long-term stability of materials. Printing platinum paste can maintain stable performance in harsh environments such as humidity and corrosion. However, long-term exposure to these environments may result in the formation of corrosion products such as oxides or sulfides on the surface of the slurry, which can affect its conductivity and stability. Therefore, a reasonable storage and usage environment is crucial for extending the service life of platinum slurry.

As mentioned earlier, long-term exposure to humid, oxygen-containing, or sulfur-containing environments,Printing platinum pastePlatinum powder in the medium may undergo oxidation or sulfurization reactions, generating corrosion products such as Ag ₂ O or Ag ₂ S. These products not only reduce the conductivity of the slurry, but may also affect its bonding strength with other materials.

As an important component of the slurry, the stability of glass adhesive directly affects the overall performance of the material. During long-term use, adhesives may be affected by environmental factors such as heat and moisture, leading to aging and issues such as decreased adhesion and microstructural changes.

Under harsh environments such as high temperature and high pressure, the microstructure of printed platinum paste may undergo evolution, such as grain growth and phase transformation. These changes may lead to material performance degradation, such as decreased conductivity and mechanical strength.

By adjusting the ratio of platinum powder, glass binder, and carrier, as well as introducing appropriate additives, the performance of printing platinum paste can be optimized and its long-term stability can be improved. Advanced Institute (Shenzhen) Technology Co., Ltd. has conducted in-depth research in this field and successfully developed various high-performance platinum slurry products.

Reasonable storage and usage environment for extensionPrinting platinum pasteThe lifespan is crucial. It is recommended to store the slurry in a dry, cool, and well ventilated place to avoid prolonged exposure to moisture, high temperatures, or corrosive environments. At the same time, process parameters should be strictly controlled during use to avoid damage to materials caused by factors such as excessive heating or mechanical stress.

For long-term use of printing platinum paste, it is recommended to conduct regular performance testing and maintenance. By detecting key indicators such as conductivity and adhesion of the slurry, signs of performance degradation can be detected in a timely manner and corresponding measures can be taken for treatment. In addition, regular maintenance and upkeep of equipment can also reduce material performance degradation caused by equipment failures.

The above data is for reference only, and specific performance may vary due to production processes and product specifications.

Advanced Institute (Shenzhen) Technology Co., Ltd, © two thousand and twenty-onewww.leird.cn. All rights reservedGuangdong ICP No. 2021051947-1 © two thousand and twenty-onewww.xianjinyuan.cn. All rights reservedGuangdong ICP No. 2021051947-2